When I work with different fabrics at Limitless Transfers, one material I often see is viscose fabric — also known as viscose rayon or “artificial silk.” This semi-synthetic material has become incredibly popular in the fashion industry, and for good reason. But what is viscose made of, and how does it work with our award-winning DTF transfers?

Understanding fabric composition is crucial for any business in the custom apparel industry. Whether you’re launching a new clothing line or expanding your product offerings, knowing how different materials interact with printing methods can make or break your success. That’s why I’m sharing everything you need to know about viscose material, from its origins to its performance with DTF transfers.

What Is Viscose Fabric (Otherwise Known as Viscose Rayon or Modal Rayon)? | Understanding a Misunderstood Fabric

Are you wondering if viscose is a synthetic or natural fabric? The answer is both.

Viscose fabric is a semi-synthetic material made from wood pulp cellulose. Despite being derived from natural sources, the extensive chemical processing involved in its production places it somewhere between natural and synthetic fibers — making it what we call a “misunderstood fabric.”

First created in the late 1800s by French scientist and industrialist Hilaire de Chardonnet, viscose was originally developed as a cheaper alternative to silk. The German Bemberg Company later commercialized it, and by 1905, the first commercial viscose rayon was hitting the market.

Viscose is also called modal rayon and artificial silk because of its smooth, drapey finish that mimics silk’s luxurious feel. This versatile fabric has secured its position as a staple in the fashion industry, particularly for dresses, blouses, and lightweight summer clothing.

What Are the Types of Viscose Fabric?

Viscose fabric, a popular semi-synthetic fiber, is derived from regenerated cellulose, which comes from organic materials like wood pulp. The manufacturing process combines natural cellulose with chemicals such as carbon disulfide to create a versatile textile fiber. This process enables the production of various types of viscose that suit different commercial and creative needs, making it a sustainable alternative for the textile industry.

One common type is regular commercial viscose, known for its affordability and widespread use in apparel like summer dresses and drapey tops. It offers a soft texture, vibrant dye absorption, and a naturally stretchy quality, making it ideal for creating lightweight, breathable garments. Bamboo viscose, another popular option, is produced from bamboo-derived cellulose and is highly regarded for its sustainability and eco-friendliness. This type of rayon boasts impressive moisture-wicking properties and is often used in athletic wear and undergarments.

Cuprammonium rayon, created using copper and ammonium compounds during production, features a silk-like texture and is commonly used in delicate items like scarves or synthetic velvet. Another variation, high-tenacity rayon filaments, is engineered for industrial purposes, such as tire cords or technical textiles, due to its enhanced strength and durability. Regardless of the type, all viscose fibers exemplify the balance of natural and synthetic properties, offering versatility in design and wearability.

Modern viscose production methods have improved substantially, with many manufacturers adopting closed-loop systems to reduce excess liquid waste and promote sustainability. This innovation makes viscose an attractive material for textile factories seeking environmentally responsible options while still delivering high-quality results. Whether choosing viscose for its drape, softness, or eco-conscious appeal, it remains a key player in the fashion and textiles industries.

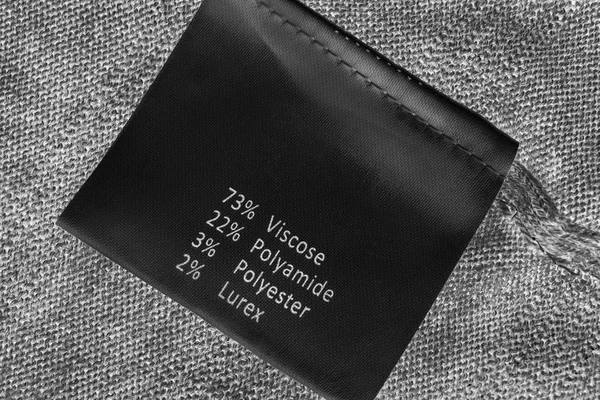

Photo by Photo By: Kaboompics.com on Pexels

The Viscose Production Process

Understanding how viscose material is made helps explain both its benefits and limitations. The viscose production process is quite complex, involving multiple chemical treatments:

- Raw Material Preparation: Natural wood pulp from trees like eucalyptus, beech, and pine is converted into alkali cellulose using sodium hydroxide.

- Processing Steps: The alkali cellulose goes through pressed sheets, then the dissolved cellulose is treated with carbon disulfide to create what’s known in the industry as viscose rayon fibers.

- Final Formation: The viscous solution is spun into rayon fibers that can be woven or knitted into fabric.

While the manufacturing processes can involve toxic chemicals like carbon disulfide and sulfuric acid, the result is a semi-synthetic material that offers unique properties for both fashion and printing applications.

Properties of Viscose Material

Advantages of Viscose Fabric

- Silk-Like Drape: Viscose offers that coveted drapey and smooth feel that makes it an excellent alternative to silk, but at a fraction of the cost.

- Lightweight and Breathable: This breathable fabric is perfect for summer dresses and activewear, as it doesn’t trap body heat like some synthetic fibers.

- Excellent Dyeability: You can easily dye viscose to produce vibrant colors, making it ideal for custom printing applications.

- Versatile Blending: Viscose works beautifully when blended with cotton fibers and synthetic fibers, creating fabrics with enhanced properties.

Disadvantages of Viscose

- Chemical-Intensive Production: The manufacturing process raises concerns for textile workers and environmental sustainability, particularly around waterways surrounding production plants.

- Care Requirements: Viscose can absorb moisture and may lose shape if not properly cared for, making it more delicate than cotton.

- Sustainability Questions: While made from natural wood pulp, the chemically intensive processes and ties to fast fashion raise environmental concerns.

Photo by Lidia Zajdzińska on Unsplash

Is Viscose Breathable?

Yes, viscose is considered a breathable fabric, especially when compared to purely synthetic fibers. This makes it an excellent choice for summer apparel like blouses, dresses, and lightweight garments. However, there’s a caveat — viscose can absorb water and may lose its shape if exposed to excessive moisture, so proper care is essential.

Is Viscose Better Than Cotton?

This depends on your specific needs. Here’s how viscose fibers compare to cotton fibers:

Cotton is a natural fiber that’s more durable and generally considered a more sustainable option. It’s stronger when wet and holds up better to repeated washing.

Viscose offers a softer drape and silk-like feel that cotton can’t match. It’s also more affordable to produce, though this comes at the cost of durability.

From my perspective, working with both materials, viscose offers unique style benefits that make it perfect for certain applications, but cotton often wins when it comes to long-term durability and eco-friendliness.

Is Viscose Good or Bad for You?

- The Good: Viscose feels soft and comfortable against the skin, making it an affordable natural material alternative to silk. It’s breathable and drapes beautifully.

- The Concerns: The production process involves toxic chemicals, which raises questions about both human health and environmental impact. Additionally, the growing fast fashion industry’s use of conventional viscose has increased these concerns.

Viscose is a bit of a misunderstood fabric — it’s amazing for fashion applications but comes with environmental and production considerations that can’t be ignored.

How Viscose Works with DTF Transfers

This is where things get interesting for those of us in the custom apparel business. Some customers use viscose rayon fabric for lightweight shirts, dresses, and other garments, and understanding how it performs with DTF transfers is crucial.

- Excellent Adhesion: DTF transfers adhere beautifully to viscose thanks to our adhesive powder, which bonds effectively with the cellulose fibers.

- Vibrant Results: The smooth surface of viscose allows our CMYK+W printing to produce incredibly vibrant prints that really make designs pop.

- Durability: When pressed correctly using proper time, temperature, and pressure, DTF transfers on viscose hold up through multiple washes while maintaining its color and integrity.

- Best Performance: Viscose works exceptionally well when it’s blended with cotton or polyester, as these blends offer enhanced durability while maintaining the drape and feel that make viscose special.

At Limitless Transfers, I’ve seen consistently great results when customers use our award-winning, true hot-peel DTF transfers on viscose apparel. Our transfers are engineered to work with a wide range of materials, and viscose is definitely one where we see excellent performance.

Frequently Asked Questions About Viscose

What are the disadvantages of viscose?

The main drawbacks include its tendency to wrinkle easily, the chemically intensive production process, and concerns about environmental sustainability. Viscose also requires more careful handling than cotton.

Is viscose better than cotton?

It depends on your priorities. Cotton is stronger and more durable, while viscose offers superior drape and a silk-like feel. For custom printing, both work well with DTF transfers, though blended fabrics often provide the best of both worlds.

Is viscose breathable?

Yes, viscose is breathable and comfortable to wear. However, it can absorb water and lose its shape when wet, so proper care is important.

Is viscose good or bad for you?

Viscose is comfortable and soft to wear, making it pleasant against the skin. However, the production process raises environmental and health concerns due to the chemicals involved in manufacturing.

Working with Viscose in Your Business | What Is Viscose Made Of?

Viscose represents an interesting opportunity for custom apparel businesses. Its silk-like appearance and affordable price point make it attractive for customers who want luxury looks without luxury prices. When combined with high-quality DTF transfers, viscose garments can deliver stunning results that keep customers coming back.

The key is understanding how to work with this material properly. Whether you’re pressing viscose blends or 100% viscose garments, using the right transfer application techniques ensures professional results every time.

No matter what fabric you’re working with — whether it’s viscose, cotton, polyester, or other fabrics — Limitless Transfers makes it easy to create durable, vibrant designs. Our hot-peel DTF transfers are engineered to perform consistently across all these different materials, giving you the confidence to expand your product offerings.

Ready to see how our award-winning DTF transfers perform on viscose and other materials? Upload your design today and experience the Limitless difference with same-day shipping and professional results that exceed expectations.