Do you know what a heat transfer printer is? Heat transfer printing has revolutionized the DIY crafting world, offering endless possibilities for personalization from the comfort of your home.

Whether you’re looking to start a business, enhance your craft, or simply create unique gifts, mastering heat transfer printing is an invaluable skill.

This guide walks you through every step, ensuring your projects turn out perfect every time.

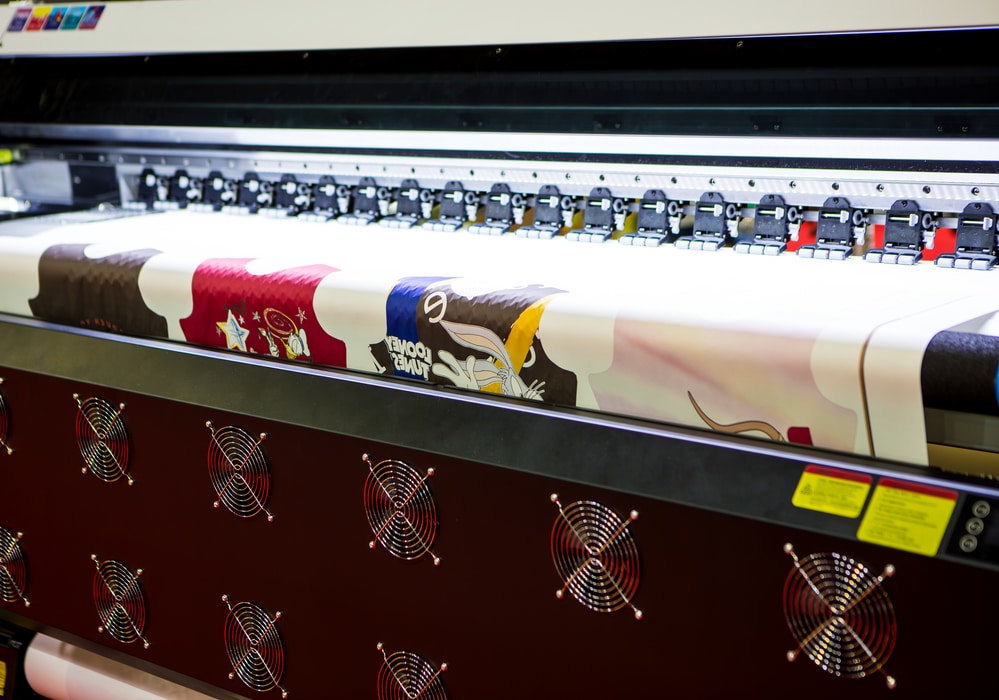

Bangkok, Thailand – March 29, 2024: Sublimation printer printing T shirt show in Print Tech 2024

What is a Heat Transfer?

Heat transfer printing, at its core, is a method of applying a design to a substrate (such as fabric, metal, or ceramic) using heat and pressure. This technique involves transferring a design from a special type of paper or vinyl onto your chosen material.

The process begins by printing your design onto heat transfer paper or cutting it out on heat transfer vinyl. The design is then placed on the substrate and subjected to high temperature and pressure using a heat press or, for smaller projects, an iron.

The heat activates the adhesive on the transfer material, causing it to bond firmly to the substrate, resulting in a high-quality and durable print.

Sublimation printer printing T shirt show in Garment and Textile Manufacturing Industry.

Projects You Can Make with Heat Transfers

Heat transfer printing unlocks a world of creativity and allows you to enhance a variety of items with your personal touch.

Here are some exciting projects to spark your imagination:

- Custom T-Shirts: Perhaps the most popular use of heat transfer is creating bespoke t-shirts. Whether it’s a unique design, a witty phrase, or your favourite artwork, you can make a personal statement on wearable items.

- Personalized Tote Bags: Eco-friendly and stylish, tote bags with custom prints make excellent gifts or promotional items. Heat transfer can be used to add logos, designs, or slogans to fabric bags.

- Decorative Pillows: Add a cozy touch to your home décor by creating decorative pillows. From intricate patterns to quotes and images, heat transfer can turn a plain pillow into a piece of art.

- Custom Mugs: With special heat transfer papers for ceramics, you can apply photos, quotes, or graphics to mugs, making them perfect for gifts or personal use.

- Phone and Laptop Cases: Personalize your gadgets by applying vinyl heat transfers to the cases. This is a great way to protect your devices while showcasing your style.

- Wall Art and Signs: Create your own wall art or decorative signs using heat transfer on canvas, wood, or metal. This can add a personal or motivational touch to any space.

Each of these projects can be tailored to fit personal preferences or desired themes, making heat transfer printing a versatile technique for DIY enthusiasts looking to express their creativity.

Introduction to the Heat Transfer Printer

Heat transfer printing involves transferring a design onto a substrate, typically fabric, using heat and pressure.

It’s a popular technique for creating custom apparel, tote bags, pillows, and more, thanks to its versatility and professional results. DIY enthusiasts love it for the personalized touch it adds to their projects.

Large format printing machine in operation. Industry

Types of Heat Transfer Printer Equipment

When venturing into the realm of heat transfer printers,it’s essential to understand the different typesof printers available, especially if you’re looking to produce high quality garments.

Each type caters to specific needs, project sizes, and levels of intricacy in designs. Here’s a quick overview:

- Inkjet Printers: Highly versatile and cost-effective, inkjet printers are the go-to for many DIY enthusiasts. They work well for both light and dark fabrics, provided you use the correct type of heat transfer paper.

- Laser Printers: Ideal for producing durable designs, laser printers are best suited for high-volume projects. They require specific heat transfer papers but offer faster printing speeds and higher quality outputs.

- Sublimation Printers: Specialized for sublimation printing, these printers produce vibrant and permanent transfers on polyester fabrics and coated substrates. They’re perfect for high-quality, full-color results.

- Direct to Garment (DTG) Printers: These printers inject pigment directly into the fabric, making them great for detailed and color-rich designs. However, they are typically more expensive and suited for those serious about garment printing.

- Direct to Film (DTF) Printers: DTF printers represent a cutting-edge option in heat transfer printing. Unlike DTG printers, DTF technology involves printing a design onto a special film which is then transferred onto the fabric. This method allows for high-quality, durable prints on a wider variety of fabrics without the need for pretreatment. DTF printers are appreciated for their flexibility, allowing creators to produce vivid, detailed designs on both light and dark textiles with excellent washability. Ideal for small to medium-sized projects, this technology combines the advantages of traditional heat transfer and DTG printing, catering to both hobbyists and professional creators looking for versatility and quality in their fabric printing endeavors.

- Plotters/Cutters for Heat Transfer Vinyl (HTV): Not traditional printers but crucial in heat transfer printing, plotters cut designs out of colored vinyl sheets. These are then heat pressed onto the fabric, offering a different texture and durability.

Each type of printer has its own set of pros and cons, depending on the specific requirements of your project. Understanding these differences is key to selecting the right printer for your heat transfer printing needs.

Big plotter printer with LED control panel

Where to Find a Heat Transfer Printer

Here are some avenues to consider when searching for a heat transfer printer:

- Online Marketplaces: Websites like Amazon, eBay, and Etsy are great places to start your search. They offer a wide selection of heat transfer printers from various brands and at different price points.

- Specialty Craft Stores: Retailers such as Michael’s, Hobby Lobby, and Joann Fabrics carry crafting printers, including models suitable for heat transfer projects. Visiting these stores allows you to see the printers in person and sometimes get live demos.

- Office Supply Stores: Staples, Office Depot, and other office supply chains often stock a variety of printers, some of which are suitable for heat transfer printing. Their staff can also provide valuable advice on the best printer for your needs.

- Manufacturer Websites: For the latest models and direct customer support, purchasing from the manufacturer’s website (such as Epson, Brother, or HP) can be a good option. They often offer detailed product specifications and warranty information.

- Professional Commercial Printing Supply Companies: These companies specialize in supplies for professional printers and businesses. They offer high-end heat transfer printers and can provide expert advice and support.

- Second-Hand or Refurbished: For budget-conscious shoppers, looking into second-hand or refurbished printers on platforms like Craigslist, Facebook Marketplace, or refurbished sections of major retailers can yield cost-effective options. Finding and selling online is a great way to find printers listed that could save you money and service your DTF station just fine!

Researching and comparing prices, warranty terms, and customer reviews across these sources can help you find the most suitable heat transfer printer for your creative projects.

Large inkjet printing machine during production on vinyl banner.

Things You Need to Know About a Heat Transfer Printer

Before you invest in a heat transfer printer, understanding the key aspects and considerations of these devices is crucial for making an informed decision.

Heat transfer printers are not just any ordinary printers; they are specifically designed or utilized in a way that supports the transfer of designs onto various substrates.

This process involves not only the printer itself but also the type of ink, heat transfer paper, and the heat press machine or iron used in the transfer. Knowing the capabilities, limitations, and operating costs of heat transfer printers can vastly improve your project outcomes and satisfaction.

From maintenance requirements to the type of materials you can print on, each detail plays a significant role in the success of your printed projects.

This introductory section aims to arm you with essential knowledge and tips to get started on the right foot with heat transfer printing.

Choosing the Right Materials

Heat Transfer Paper

- Light vs. Dark Paper: Choose light transfer paper for lighter fabrics and dark transfer paper for darker materials. Specialty papers are also available for unique projects.

- Fabric Selection: Opt for smooth, solid-colored fabrics for the best results. Both natural fibers like cotton and synthetic materials like polyester work well, but ensure they’re compatible with heat transfer.

Quality is key. Ensure your materials are of good quality, free from wrinkles or textures that might hinder the transfer process.

Setting Up Your Heat Transfer Printer

- Unboxing and Inspection: Carefully unbox your printer, checking for any damage.

- Ink and Software: Install the ink cartridges as directed and load the software onto your computer. This might include drivers or design software recommended by the manufacturer.

- Connectivity: Connect your printer to your device. This could be through a USB cable or wireless connection, depending on your model.

Designing Your Project

- Software Choices: Use Adobe Illustrator or free online tools for designing. Ensure your design is appropriately sized and positioned for your project.

- File Formats: Save your design in a format compatible with heat transfer printing, typically as a PNG or PDF for high-quality results.

Printing Your Design

- Load Material: Place the heat transfer paper in your printer tray. Ensure it’s positioned correctly according to the manufacturer’s guidelines.

- Adjust Settings: Select the correct settings on your printer for the type of paper and quality of print you desire. This might include choosing a ‘mirror image’ option for certain types of transfers.

- Test Print: Always run a test print on a regular sheet of paper to confirm your design’s size and positioning are correct.

Heat Pressing Your Transfer

- Heat Press Setup: Preheat your heat press machine, adjusting time, temperature, and pressure settings based on your specific materials.

- Positioning: Place your fabric on the platen, then position the printed transfer paper face down on the fabric.

- Pressing: Close the heat press and apply heat and pressure as required. Once completed, peel off the transfer paper while hot or cold, depending on the instructions.

Finishing and Care Instructions

- Cool Down: Allow your fabric to cool before handling.

- Peeling: Gently peel the backing paper away from the fabric.

- Care: Wash your fabric inside out on a gentle cycle to maintain the quality of the transfer.

Troubleshooting

Encounter issues? Here are quick fixes:

- Fading or Peeling: Check your heat press settings. Incorrect temperature or pressure can cause this.

- Misprints: Ensure your printer is loaded correctly and settings are adjusted for the type of transfer paper you’re using.

Conclusion

Heat transfer printing opens up a world of creativity and personalization for DIY enthusiasts. With the right materials, setup, and care, your projects will come to life in vibrant color and detail.

Remember, practice makes perfect, so don’t be afraid to experiment.

If you’re looking to have DTF (Direct to Film) Transfers printed and don’t have the resources, reach out to us at Limitless Transfers. We not only offer high-quality DTF printing services but also sell heat presses and other supplies to get you started.

Visit our website for more information, and explore our products and educational resources to ensure your success in heat transfer printing.