Do you know what vinyl cutter machines are? In the world of DIY, crafting, and small business, there’s a revolutionary tool that’s been quietly transforming creative processes for decades.

Imagine a device that can intricately cut customizable designs out of vinyl, from small decals to large signs, with precision and speed that only your imagination can limit. Enter the world of vinyl cutters, a must-have for anyone looking to elevate their projects or embark on a new entrepreneurial journey.

Let’s explore what a vinyl cutter is, how it works, and the endless possibilities it brings to the table—quite literally. Welcome to the cutting-edge.

Introduction to Vinyl Cutters

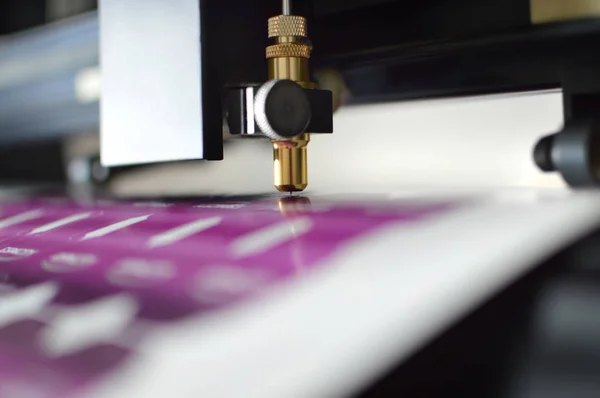

A vinyl cutter is a computer-controlled machine that precisely cuts intricate designs, letters, and shapes out of adhesive vinyl. This versatile tool is commonly used in the DIY, crafting, and small business sectors. Vinyl cutters operate by following digital designs, which can be created using compatible software or imported from existing files.

The machine then precisely cuts the design into the vinyl using a small blade, allowing for detailed and professional-quality results. With the ability to work with various vinyl types, including heat transfer vinyl (HTV) for apparel and adhesive vinyl for signs and decals, these machines have become essential for anyone looking to add a personal touch or professional finish.

Relevance in DIY, Crafting, and Small Business Sectors

Vinyl cutters are game-changers for DIY enthusiasts, crafters, and small business owners. For DIY enthusiasts, a vinyl cutter offers endless possibilities for home decor, personal projects, and gifts. Crafters can elevate their projects, from scrapbooking to card-making, with precision and detail that was previously hard to achieve.

Small businesses, especially those in custom apparel, signage, and promotional products, benefit immensely from the efficiency and quality of vinyl cutters. The technology allows for quick turnovers and high-quality results, making it a valuable investment.

Engaging Introduction to Draw In Readers

Imagine transforming your creative ideas into reality with just a few clicks. Imagine enhancing your business offerings with customized, high-quality products that stand out.

A vinyl cutter can do just that. This blog post will guide you through understanding what a vinyl cutter is, how it works, and how it can revolutionize your projects and business. Let’s cut to the chase and explore the world of vinyl cutters.

How A Vinyl Cutter Works

At its core, a vinyl cutter operates by following a digital design, which can be created using compatible software or imported from existing files. Once the design is ready, the vinyl cutter uses a small, incredibly sharp blade to cut the design into the vinyl material.

The vinyl plotter is fed into the machine, and the blade moves according to the digital design’s instructions. This process allows for intricate and precise cuts, making it possible to create detailed designs, letters, and shapes.

The Technology Behind Precision Cutting

The precision of vinyl cutters is made possible by advanced technology. Most vinyl cutters use a combination of mechanical and electrical components to ensure accurate cutting. Stepper motors control the movement of the blade, allowing it to move in small, precise increments.

Additionally, the blade’s downforce can be adjusted to accommodate different types of vinyl and varying thicknesses. This technology ensures that every cut is clean and precise, resulting in professional-quality designs.

The Versatility of Vinyl Cutters

Vinyl cutters are incredibly versatile and can be used for a wide range of applications. They are commonly used to create signs, decals, and custom apparel. For instance, businesses can use vinyl cutters to produce eye-catching signs and banners for advertising and events.

Decals made with vinyl cutters can be used for vehicle graphics, window displays, and home decor. In the apparel industry, heat transfer vinyl (HTV) can be cut and applied to create custom t-shirts, hoodies, and other clothing items.

Choosing the Right Vinyl Cutter

Choosing the right vinyl cutter depends on several factors, including speed, size, and model. Speed is crucial for businesses that need to produce large quantities of products quickly.

The size of the cutter determines the maximum width of the vinyl that can be used, which is important for creating larger designs. Additionally, different models offer various features, such as advanced software compatibility, adjustable downforce, and ease of use. It’s essential to consider these factors based on your specific needs and projects.

Overview of Popular Brands Like Roland DG

Several reputable brands manufacture high-quality vinyl cutters, with Roland DG being one of the most popular. Roland DG is known for producing reliable and efficient vinyl cutters that cater to various needs.

Their machines are user-friendly and come with advanced features, making them suitable for both beginners and professionals. Other notable brands include Cricut, Silhouette, and Graphtec, each offering a range of models with unique features and capabilities.

Popular Vinyl Cutters

Here’s a list of some of the most popular vinyl cutters available on the market today, each known for its unique features and capabilities:

- Roland DG – Roland DG Vinyl Cutters: Renowned for reliability and precision, suitable for both beginners and professionals.

- Cricut – Cricut Vinyl Cutters: Offers user-friendly machines ideal for craft enthusiasts, with a range of features for personal and professional use.

- Silhouette – Silhouette Vinyl Cutters: Known for their versatile cutting capabilities, perfect for creating detailed designs and crafts.

- Graphtec – Graphtec Vinyl Cutters Provides high-precision cutting machines with advanced technology, ideal for serious crafters and businesses.

- USCutter – USCutter Vinyl Cutters: Offers a wide selection of affordable vinyl cutters designed to meet the needs of various users, from hobbyists to professionals.

These brands provide a diverse range of options to help you find the perfect vinyl cutter for your projects or business needs.

Getting Started with Vinyl Cutting

To get started with vinyl cutting, you’ll need a few essential pieces of equipment and materials. First and foremost, you’ll need a vinyl cutter and compatible software to create your designs.

Additionally, you’ll need vinyl sheets, transfer tape, and a weeding tool to remove excess vinyl. For heat transfer projects, a heat press is necessary to apply the vinyl to the fabric. Having the right tools and materials ensures a smooth and successful vinyl-cutting experience.

Basic Steps and Best Practices for Beginners

Starting with vinyl cutting is easier than you might think. Here are some basic steps and best practices for beginners:

- Design Creation: Use software to create or import your design. Ensure that the design is compatible with your vinyl cutter.

- Cutting: Load the vinyl into the cutter and set the appropriate settings for speed and downforce. Start the cutting process and monitor the progress.

- Weeding: Once the cutting is complete, use a weeding tool to remove excess vinyl from the design.

- Application: Apply transfer tape to the design and transfer it to the desired surface. For heat transfer projects, use a heat press to apply the vinyl to the fabric.

Following these steps and practicing regularly will help you master vinyl cutting in no time.

Maintenance and Care for Vinyl Cutters

Proper maintenance and care are essential to keep your vinyl cutter in optimal condition. Here are some tips to ensure your machine’s longevity:

- Regular Cleaning: Clean the machine regularly to remove dust and debris that can affect performance. Pay special attention to the blade and cutting mat.

- Blade Replacement: Replace the blade as needed to ensure clean and precise cuts. Dull blades can result in poor-quality cuts and damage to the vinyl.

- Software Updates: Keep your software updated to benefit from the latest features and improvements.

By following these maintenance tips, you can ensure your vinyl cutter remains in top condition and delivers consistent results.

Common Troubleshooting and Maintenance Tasks

Even with proper maintenance, you may encounter issues with your vinyl cutter. Some common troubleshooting and maintenance tasks include:

- Blade Adjustment: If the blade depth is incorrect, it can cause issues with cutting. Adjust the blade depth according to the vinyl thickness.

- Calibration: Periodically calibrate the machine to ensure accurate cuts. Refer to the manufacturer’s instructions for calibration procedures.

- Software Issues: If you experience software problems, check for updates or reinstall the software. Consult the user manual or support resources for assistance.

Addressing these common issues promptly will help maintain your machine’s performance.

DTF Transfers Are Superior Because You Don’t Need a Vinyl Cutter

Direct-to-film (DTF) transfers are revolutionizing the way designs are transferred onto various materials, providing a number of advantages over traditional vinyl cutting methods.

One of the most significant benefits of DTF transfers is the elimination of the need for a vinyl cutter. This streamlines the process, making it both time-efficient and cost-effective for users.

Advantages of DTF Transfers

- Ease of Use: DTF transfers allow for quick and straightforward design application without the need for intricate cutting adjustments. Users can simply print their designs onto a special transfer film and then apply them to the target material using a heat press.

- Versatile Material Compatibility: Unlike vinyl cuts that may be limited by material types, DTF transfers can be applied to a wider range of fabrics and surfaces, including cotton, polyester, and blends. This versatility opens up new possibilities for creative projects and product offerings.

- Vivid Color and Detail: DTF technology enables high-resolution printing with vibrant colors and intricate details, surpassing the capabilities of vinyl in many cases. This results in stunning end products that draw attention.

- Reduced Waste: By bypassing the cutting process, DTF technology reduces material waste associated with leftover vinyl scraps. This is especially beneficial for businesses aiming to operate sustainably.

In summary, DTF transfers stand out as a superior alternative for those looking to enhance their design capabilities without the need for a vinyl cutter, providing advantages in ease of use, material compatibility, and quality.

Order Your DTF Transfers from Us at Limitless Transfers

When it comes to sourcing high-quality Direct-to-Film (DTF) transfers, look no further than Limitless Transfers.

We specialize in providing a wide range of vibrant, durable, and intricately designed DTF transfers that cater to various projects and quick-view business needs. Ordering from us is simple and efficient, ensuring that you receive your transfers quickly and hassle-free. Whether you’re making a sign, or shirt in various sizes, the choice is yours and Limitless Transfers is here to help!

Why Choose Limitless Transfers?

- Quality Assurance: Our DTF transfers are made using top-of-the-line technology, guaranteeing vibrant colors and excellent detail on any fabric or surface.

- Custom Options: We offer the flexibility to create custom designs tailored to your specific requirements, allowing your creativity to shine through in every project.

- Fast Turnaround: We understand the importance of time in your projects, which is why we prioritize quick processing and delivery of your orders.

- Exceptional Support: Our dedicated customer service team is available to assist you throughout the ordering process, ensuring that you have a seamless experience.

Take your projects to the next level with our premium DTF transfers. Visit our website or contact us today to get started

Conclusion

Vinyl cutters have revolutionized the world of DIY, crafting, and small business by providing a versatile and efficient tool for creating custom designs.

From signs and decals to apparel and unique projects, the possibilities are endless. By understanding how vinyl cutters work, choosing the right machine, and following best practices, you can unlock your creativity and take your projects to the next level.

Whether you’re a DIY enthusiast, crafter, or small business owner, a vinyl cutter is a valuable investment that can enhance your work and open up new opportunities.

Explore the world of vinyl cutting, experiment with different projects, and see the incredible results for yourself.

Ready to get started? Consider incorporating a vinyl cutter into your toolkit and watch your creativity soar. Or skip the vinyl cutter entirely and order your DTF Transfers today!