Screen Printing is a popular and versatile printing method used for everything from t-shirts to signs. While the process can be daunting for beginners, screen print transfers make it easy to get started. Here’s what you need to know about wholesale screen print transfers!

First Off, What Is Screen Printing?

The process of screen printing also called silk screening or silk screen printing, is when you use a mesh screen with plastisol inks and a squeegee (a rubber blade) to transfer a stenciled design onto another surface. The basic steps involve making a stencil on the mesh screen and then pushing the ink through so that it creates an imprint of the design below.

Paper and fabric are the most common materials used in screen printing, but metal, wood, and plastic can also be utilized. It is a very popular method for a variety of reasons, including the wide range of colors that may be used.

When To Choose Custom Screen Printed Transfers?

When there are a large number of items to print, some transfer methods, such as vinyl or color-cut-out transfer, may be too time-consuming and laborious. Screen-printed transfers would be the better alternative in this situation.

Because the set-up procedure is identical to screen printing for smaller quantities, costs can be rather high, but there are significant savings: the more you buy, the cheaper it gets.

Another thing to think about is the color matching procedure. Other methods of transferring use a CMYK printing process, but screen-printed transfers are Pantone matched, so you may get accurate Pantone colors if you want to adhere to brand guidelines and create an exact Pantone color.

What Screen Printing Method Should You Choose?

There are six different types of screen printing processes. Since different techniques will provide different results, it is important to understand the different types.

1. Grayscale Printing

Grayscale printing is a great method to produce full-color pictures in one-color grayscales or halftones. If the halftone has more dots, the print will appear more detailed. It’s not black and white; rather, it just uses CMYK, RGB, and/or color scales in shades of grey. Grayscale printing is a very cost-effective way to screen print on textiles since it only utilizes black and white ink.

2. Halftone Printing

Halftone printing is a technique that uses single colors in gradients. The entire process uses only one color of ink, which is then halftoned to produce different shades when viewed from a distance. This technique is best used to obtain the multi-color printing look without actually doing it. In addition, it is a cost-effective method since only one color of ink is needed.

3. Spot Color Printing

Spot color screen printing is probably the most prevalent type of screen printing. It involves using ink in its stock color and running it through a stencil on mesh, which results in a beautiful solid spot of that color. Additionally, it is simpler to use than other methods of screen printing and works great for garments like t-shirts, jackets, and hoodies.

4. CMYK Printing

CMYK printing is a complex process that usually involves four colors – cyan, magenta, yellow, and black. These colors are combined to create the desired color tones. Although it can be done by hand, using an automatic machine will produce better results.

5. Duotone Printing

The technique of duotone printing entails combining two halftones to achieve the same picture with two hues. A black halftone is first printed in black ink, and then a second color halftone is created by adding white ink. This method resembles sepia-toned photography in its sophisticated and artistic look.

6. Simulated Process Printing

The simulated printing process is a mix of the four-color printing process and spot color printing, which comes in handy for both light and dark shades. Its versatility makes it a go-to choice for people looking to create incredibly realistic print detail.

How Does It Work?

Below, we share the process of screen printing step by step:

Start By Creating Your Design

The first thing you need to do for screen printing is come up with a design. Once you have your design, print it out onto a clear acetate sheet. This will be used to make the stencil for your final product.

Prepare Your Screen

When the design is complete, it’s time to choose the screen and mesh count. The total number of fibers in one square inch is known as a mesh count. The mesh count you require will vary based on the design being manufactured. A higher mesh count can print finer details while preserving a fair coating of ink. Screens with a low mesh count have wider openings, which lets the water-based or plastisol ink flow through more easily. After you select the screen, coat it with a light-reactive emulsion layer. Usually, there are three main types of emulsions:

SBQ: This expensive general-purpose emulsion is straightforward to apply and easy to use.

Diazo: This needs longer exposure to light and is not quite suitable for detailed prints.

Dual-cure emulsions: This product combines Diazo and SBQ to create a final result that takes less time than diazo and is less expensive than SBQ.

Expose The Emulsion

The transparent acetate film is carefully applied to the emulsion-coated mesh screen under bright light, causing the emulsion to solidify and mature. When many colors are used in the design, separate screens must be utilized for each color.

Create The Stencil

The process of hardening the screen begins with exposing it to light. This will cure, or harden, the emulsion that was previously coated on the mesh. The remaining unhardened emulsion is then rinsed away, leaving a clear stencil of your design on the screen. Finally, the screen is dried, and any touch-ups required are completed by the printer. After this, the screen is put on top of the material that is ready to be printed on,

Apply The Design & Cure

During this step, the screen is lowered to the printing board. The required color ink is sprayed onto the top of the screen. Squeezing uniformly distributes ink down the length of the screen with a squeegee. As a result, the design is printed on the product as it passes through these openings in the stencil and onto the underlying silk.

After the stencils have been created, they are then washed with a special fluid to remove any leftover emulsion. This way, the mesh can be reused to create new stencils.

After the design has been printed, it must go through a heat-curing process to set the ink. This is typically done with a conveyor dryer, which uses hot air to evaporate the solvents in the ink and cure the print. Once the ink is dry, it is safe to handle, and the product is ready to be used or worn.

Why Should You Use Screen Printing For Wholesale?

There are several reasons why screen printing is such a popular printing method, especially when it comes to printing products in bulk. Here are some of the main benefits of screen printing:

1. It’s Affordable

Screen printing is one of the most affordable printing methods, especially when you need to print large quantities of products. The set-up costs are high at first, but once you have your screens made, you can reuse them multiple times.

2. It’s Versatile

Screen printing can be used on a variety of materials, including paper, cardstock, fabric, glass, metal, and more. This makes it a great option for a wide range of products, from t-shirts to coffee mugs.

3. It’s Durable

Screen printing is a very durable printing method. The ink is applied thickly and evenly, which helps it to withstand wear and tear. This makes screen-printed products perfect for items that will be used on a daily basis, such as water bottles and dish towels.

4. Efficient

Screen printing is a very efficient process, especially when printing in bulk. Once the screens are set up, you can print large quantities of products quickly and easily. Aside from this, the screen printing technique is simple to learn and execute, whether it’s done automatically or manually. Furthermore, the necessary instruments are also easy to acquire.

5. It Creates A Professional Finish

Screen printing produces a clean, professional finish that looks great on any product. This is why it’s often used for promotional items.

Screen Printing Uses And Applications

Screen printing is a versatile printing method that can be used for a wide range of products. Here are some common examples:

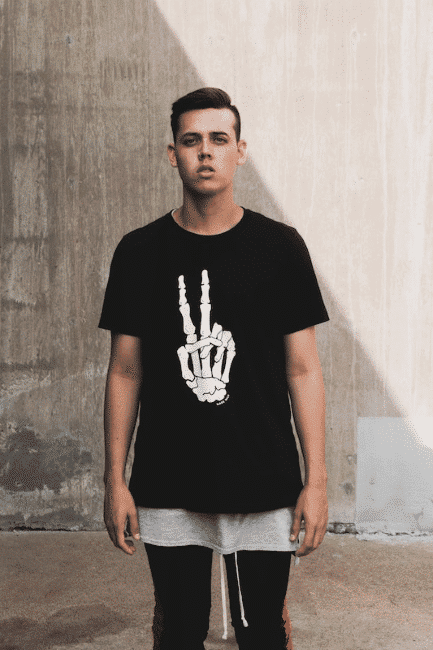

-T-shirts

-Coffee mugs

-Water bottles

-Dish towels

-Promotional items (pens, keychains, etc.)

-Posters

-Art prints

-Canvas bags

-Tote bags

-Fabric banners

-And more!

Looking for other forms of printing? Check out heat press transfers in this blog post. *

Bottom Line

If you’re looking for a reliable and affordable printing method for your wholesale custom transfers, screen printing is definitely worth considering. With its versatile nature, durability, efficiency, and professional finish, it’s no wonder that screen printing is one of the most popular printing methods around.