The world of custom apparel is constantly evolving, and DTF (Direct to Film) transfers have emerged as a game-changer for creatives, small businesses, and print shops alike. Whether you’re looking to start your own t-shirt line, expand your crafting business, or fulfill large, custom orders for clients, DTF transfers offer unmatched quality, versatility, and ease of use.

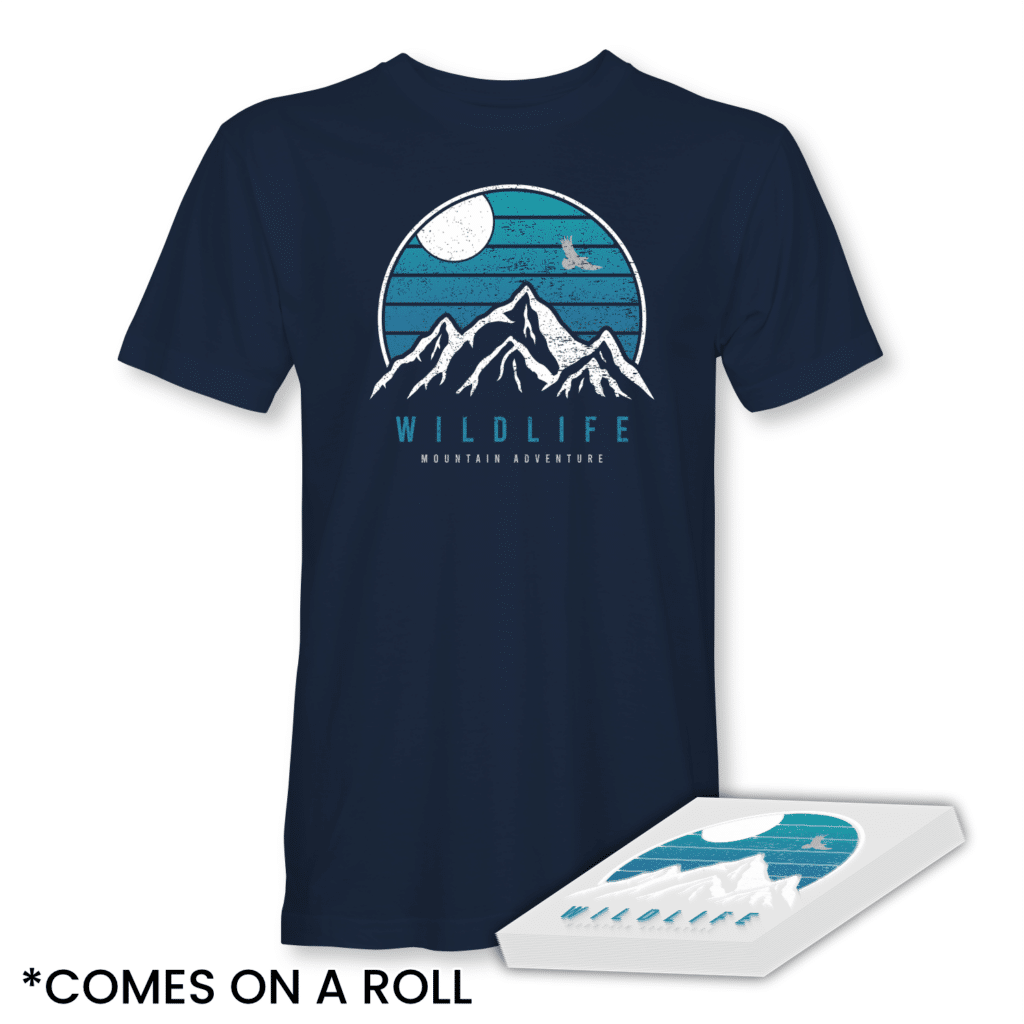

Limitless Transfers offers a variety of DTF transfer types, including color DTF transfers—ideal for vibrant, high-quality images on various fabrics—and glitter DTF, which features embedded glitter particles for a unique, eye-catching effect.

At Limitless Transfers, we specialize in providing high-quality custom DTF transfers with standout benefits like free shipping on orders over $50, no setup fees, and fast turnaround times. We are dedicated to customer satisfaction by ensuring quality, reliable products, and responsive support to exceed your expectations.

This guide will take you through everything you need to know about DTF transfers, including how they compare to other methods, how to use them, and what sets Limitless Transfers apart from competitors.

What Are DTF Transfers?

DTF transfers, also known as direct-to-film DTF, are a revolutionary heat transfer printing method designed for creating custom designs, logos, or images on a variety of materials and fabrics.

The process involves printing the main image or artwork onto a special film, which is then transferred onto a surface like a t-shirt or tote bag using heat and pressure.

Unlike traditional screen printing, which has high setup costs and limited color options, or vinyl methods that can feel thick and require more effort, direct-to-film DTF offers a more flexible, detailed, and lightweight solution for apparel decoration.

How Do They Work?

- Printing: The design is digitally printed onto a PET film using specialized ink and a layer of white to ensure opacity.

- Powder Application: A heat-activated adhesive powder is applied to the print, ensuring it bonds securely to the fabric.

- Curing: The film is heated to cure the adhesive powder.

- Transfer: The design is placed onto the fabric and pressed with a heat press, completing the transfer process.

DTF prints feature a white underbase for excellent visibility on dark fabrics, and are known for their durability, wash resistance, and soft feel compared to other transfer methods.

Why Choose DTF Over Other Methods?

- Part of the broader family of heat transfers, DTF stands out among custom heat transfers for its superior versatility and detail.

- Versatility: Works on cotton, polyester, nylon, tri-blends, and even leather.

- Durability: Produces long-lasting designs that resist cracking or peeling, making it a reliable heat transfer solution.

- Vibrancy: Delivers sharp details and rich, vibrant colors, ideal for custom heat transfers on apparel and promotional items.

- Cost-Effective: No need for screens or extensive setups, making it ideal for large and small orders alike.

DTF Transfer Materials: What You Need to Know

The foundation of every great DTF transfer lies in the materials used. DTF transfers are crafted from a specialized PET film that’s engineered to deliver high-quality, durable results on a wide range of fabrics. This film, combined with premium adhesive powders, ensures that your custom designs bond securely to garments, creating vibrant, long-lasting prints.

When selecting materials for your custom DTF gang sheets, it’s important to consider the type of fabric you’ll be working with—whether it’s cotton, polyester, blends, or even more challenging textiles. The right DTF transfer material will provide excellent opacity and flexibility, making it ideal for both light and dark garments.

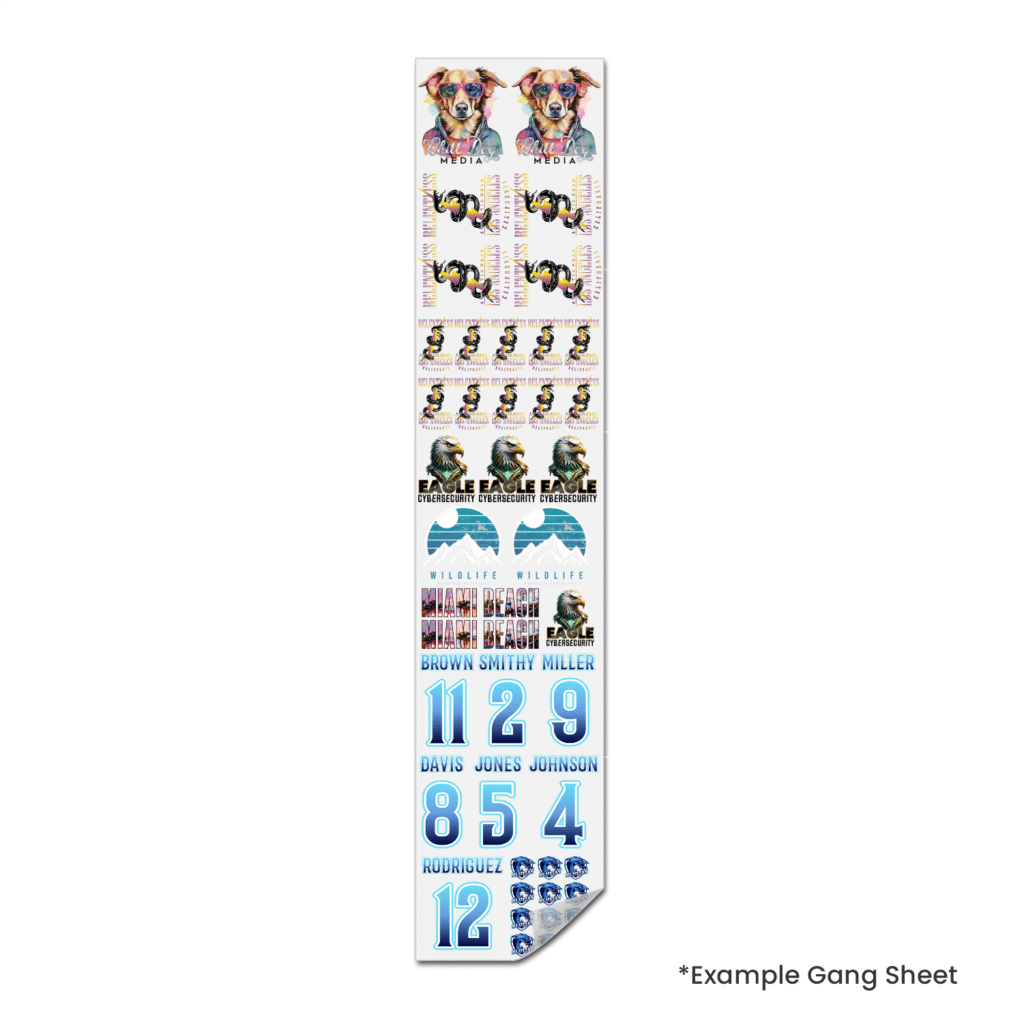

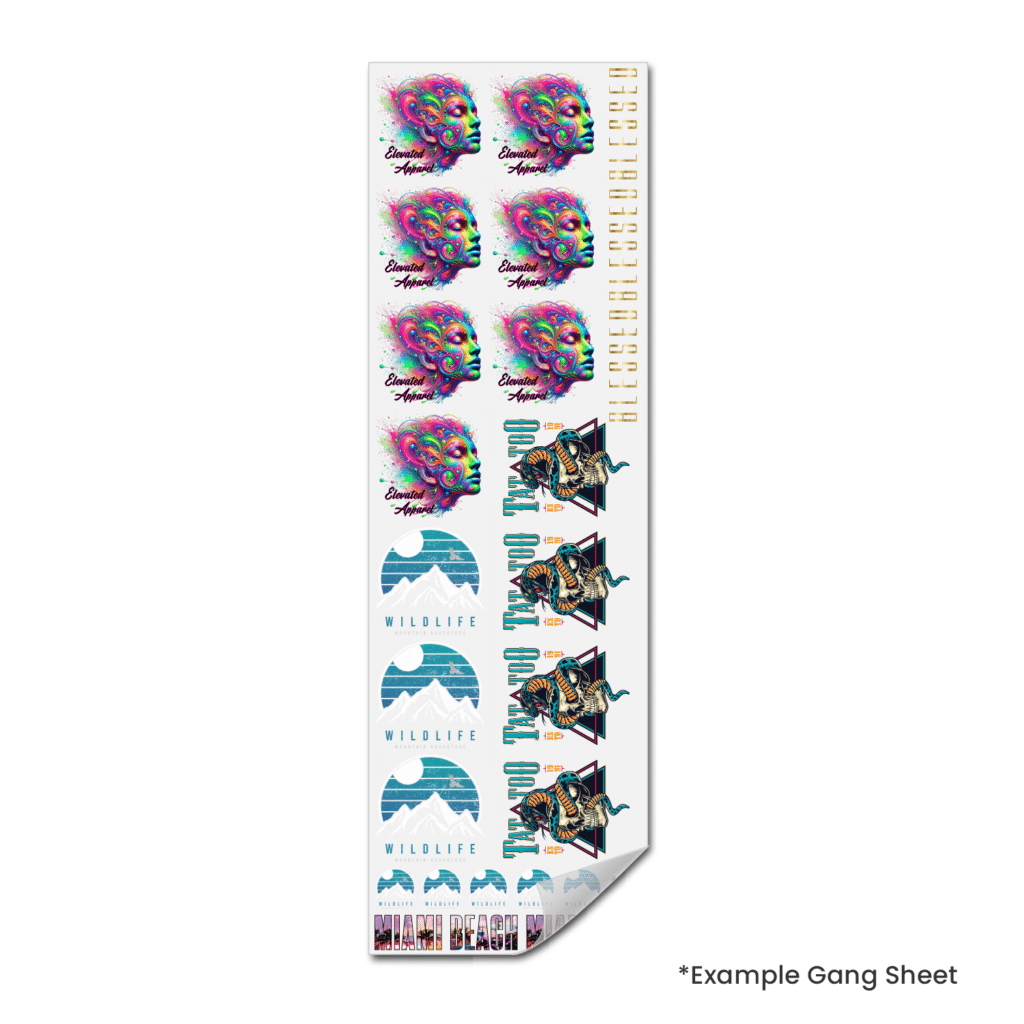

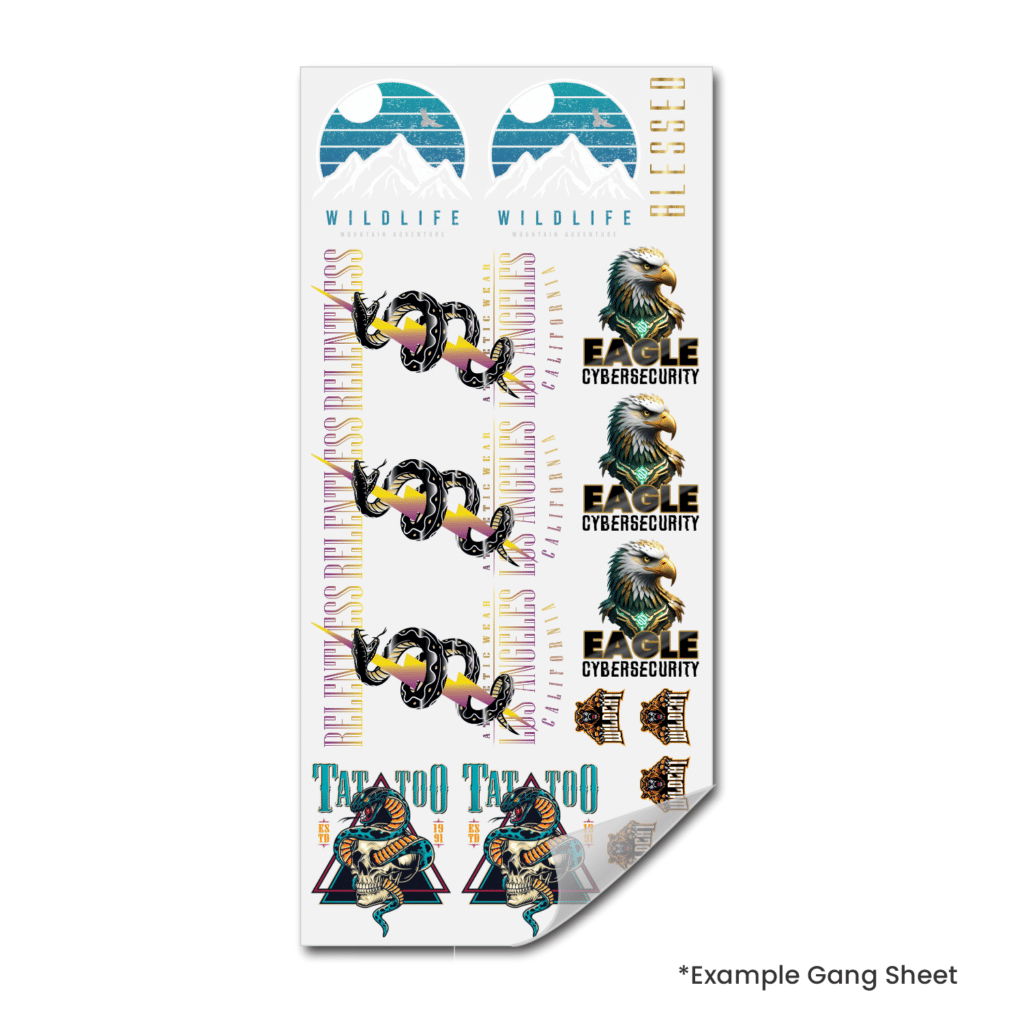

Custom DTF gang sheets are especially popular for those looking to create multiple designs on a single sheet, maximizing efficiency and reducing waste during the transfer process.

Whether you’re producing custom apparel for your brand or fulfilling bulk orders, using high-quality DTF gang sheets ensures that every transfer meets your standards for color, clarity, and durability. With the right materials, you can create custom t-shirts, tote bags, and more, all with professional-grade results.

DTF Transfer Equipment: Essential Tools for Success

Achieving professional results with DTF transfers starts with having the right equipment. The most critical tool in your setup is a reliable heat press, which provides the consistent heat and firm pressure needed to bond the transfer to your garment.

A high-quality heat press ensures that your DTF transfers adhere smoothly, resulting in sharp details and vibrant colors that stand out on any fabric.

In addition to a heat press, you’ll need a compatible printer capable of producing high quality DTF transfers, a cutting machine for precise trimming, and a computer equipped with design software.

When choosing a heat press, look for features like adjustable temperature controls, even pressure distribution, and a size that matches your typical project needs. These factors all contribute to the overall quality of your transfers and the ease of your workflow.

With the right equipment, you can confidently press your DTF transfers, knowing that each print will showcase the vivid colors and crisp details that set your custom apparel apart.

DTF Transfer Software: Powering Your Designs

The customization process for DTF transfers begins with powerful design software. Programs like Adobe Photoshop and Corel Draw are industry favorites, offering a wide range of tools to help you create custom designs, edit artwork, and prepare files for printing.

These programs allow you to fine-tune every detail, from color adjustments to intricate design elements, ensuring your artwork is truly print ready.

A good DTF transfer software should be user-friendly, compatible with your printer, and capable of handling multiple designs for efficient gang sheet creation.

By using software that supports custom gang sheets, you can optimize your printing process, reduce material waste, and streamline production. Whether you’re designing for a single t-shirt or a full run of custom apparel, the right software empowers you to bring your creative vision to life with precision and ease.

With robust design tools at your fingertips, you can create, edit, and finalize artwork that translates perfectly from screen to transfer, ensuring every print meets your standards for quality and originality.

DTF Transfer Materials: What You Need to Know

The foundation of every great DTF transfer lies in the materials used. DTF transfers are crafted from a specialized PET film that’s engineered to deliver high-quality, durable results on a wide range of fabrics. This film, combined with premium adhesive powders, ensures that your custom designs bond securely to garments, creating vibrant, long-lasting prints.

When selecting materials for your custom DTF gang sheets, it’s important to consider the type of fabric you’ll be working with—whether it’s cotton, polyester, blends, or even more challenging textiles.

The right DTF transfer material will provide excellent opacity and flexibility, making it ideal for both light and dark garments. Custom DTF gang sheets are especially popular for those looking to create multiple designs on a single sheet, maximizing efficiency and reducing waste during the transfer process.

Whether you’re producing custom apparel for your brand or fulfilling bulk orders, using high-quality DTF gang sheets ensures that every transfer meets your standards for color, clarity, and durability. With the right materials, you can create custom t-shirts, tote bags, and more, all with professional-grade results.

DTF Transfer Equipment: Essential Tools for Success

Achieving professional results with DTF transfers starts with having the right equipment. The most critical tool in your setup is a reliable heat press, which provides the consistent heat and firm pressure needed to bond the transfer to your garment.

A high-quality heat press ensures that your DTF transfers adhere smoothly, resulting in sharp details and vibrant colors that stand out on any fabric.

In addition to a heat press, you’ll need a compatible printer capable of producing high quality DTF transfers, a cutting machine for precise trimming, and a computer equipped with design software. When choosing a heat press, look for features like adjustable temperature controls, even pressure distribution, and a size that matches your typical project needs.

These factors all contribute to the overall quality of your transfers and the ease of your workflow.

With the right equipment, you can confidently press your DTF transfers, knowing that each print will showcase the vivid colors and crisp details that set your custom apparel apart.

DTF Transfer Software: Powering Your Designs

The customization process for DTF transfers begins with powerful design software. Programs like Adobe Photoshop and Corel Draw are industry favorites, offering a wide range of tools to help you create custom designs, edit artwork, and prepare files for printing.

These programs allow you to fine-tune every detail, from color adjustments to intricate design elements, ensuring your artwork is truly print ready.

A good DTF transfer software should be user-friendly, compatible with your printer, and capable of handling multiple designs for efficient gang sheet creation.

By using software that supports custom gang sheets, you can optimize your printing process, reduce material waste, and streamline production. Whether you’re designing for a single t-shirt or a full run of custom apparel, the right software empowers you to bring your creative vision to life with precision and ease.

With robust design tools at your fingertips, you can create, edit, and finalize artwork that translates perfectly from screen to transfer, ensuring every print meets your standards for quality and originality.

Why Limitless Transfers is Your Ideal Partner for Custom DTF Solutions

At Limitless Transfers, we pride ourselves on providing unmatched quality and a seamless ordering experience. Here’s why we stand out:

- Our simple ordering process lets you simply upload your artwork or designs—no hassle, just quick results.

- Easily upload multiple designs at once for our custom heat transfer solutions, perfect for vibrant, durable, and scalable custom apparel and merchandise.

Unique Selling Points

- Free Shipping on Orders Over $50 | Save money without compromising on quality. We offer free UPS Ground shipping, making it even easier to stock up on transfers.

- No Setup Fees or Minimum Orders | Whether you’re starting small or fulfilling bulk orders, we make it easy with absolutely no minimums or hidden fees.

- Cutting-Edge Technology | Our state-of-the-art DTF printers ensure high color accuracy and vibrancy, producing fantastic results with every order.

- Support for Every Business Model | From small businesses to large-scale operations, we cater to every need with customizable options, including gang sheets, by-size transfers, and even equipment for DIY projects.

- Fast Turnaround Times | Place your orders with confidence knowing we ship same-day for orders received by noon EST.

Can I Make My Own DTF Transfers?

The DIY route for making DTF transfers is possible if you’re equipped with the necessary tools, including a DTF printer, PET film, adhesive powder, and curing equipment.

While making your own transfers may seem appealing, there are important considerations to weigh.

Pros and Cons of DIY vs. Professional Services

DIY Pros:

- Full creative control over the process.

- Potential cost savings for frequent high-volume production.

DIY Cons:

- High initial investment in specialized equipment.

- A steep learning curve and potential for errors.

- Time-consuming process that could divert focus from other aspects of your business.

Ordering from a trusted professional service like Limitless Transfers ensures consistent quality, vibrant colors, and accurate results every time. Plus, we handle the hard work for you!

Is Making Your Own DTF Transfers Worth It?

A Quick Cost Analysis:

- DIY Equipment Investment: Setting up with a reliable DTF printer and supplies can cost upwards of $5,000–$10,000.

- Time Investment: Perfecting the technique could take months, especially if you’re unfamiliar with DTF-specific processes.

- Professional Service: Limitless Transfers eliminates upfront costs and delivers consistent results without the extra hassle.

Verdict: For most small businesses or crafters, relying on a professional service like Limitless Transfers is far more cost-effective and time-efficient.

DTF vs. Sublimation Printing: Which is Better?

DTF transfers and sublimation are two popular methods for garment customization, but they have distinct applications.

|

Feature |

DTF Transfers |

Sublimation Printing |

|---|---|---|

|

Compatibility |

Works on almost any fabric, including dark garments |

Only works on polyester or polymer-coated items |

|

Color Vibrancy |

Sharp, vibrant colors |

Excellent vibrancy on light fabrics |

|

Durability |

Extremely durable; resists cracking |

Durable but less versatile in application |

|

Upfront Costs |

Moderate |

Moderate |

Screen print transfers are another popular option for custom print transfers, offering lower minimum orders and easy customization. However, DTF transfers provide greater flexibility and detail for custom orders compared to both screen print transfers and sublimation.

Ideal for:

- DTF is better for dark garments, mixed fabrics, and a wider range of materials.

- Sublimation works great for white or light-colored polyester items.

Can I Convert My Printer for DTF Transfers?

Converting an existing inkjet printer into a DTF printer is technically feasible but comes with risks:

- Required Modifications: Adjustments to hardware and software, along with using DTF inks.

- Challenges: Increased maintenance needs, decreased printer lifespan, and potential for clogs or errors.

- Professional Alternatives: Save time, effort, and resources by partnering with Limitless Transfers for all your DTF needs.

Optimizing Your Designs for DTF Transfers

File Types and Resolution

- Use PDFs or PNGs with transparent backgrounds.

- Minimum resolution of 300 DPI to maintain sharpness.

Color Considerations

- Convert colors to CMYK for accurate printing.

- Avoid heavily compressed images to ensure vibrant results.

Best Practices

- Ensure edges of designs are clean.

- Test darker designs on light garments for contrast.

Heat Pressing DTF Transfers Like a Pro

Here are detailed application instructions for applying your custom heat transfers using the heat transfer method.

These steps include recommended equipment, temperature, pressure, peeling technique, and protective measures to ensure a successful transfer:

- Prepare the Garment | Lay the fabric on the heat press and smooth out any wrinkles. Use a lint roller if needed to remove debris.

- Position the Transfer | Place your DTF transfer film face down, ensuring proper alignment for your custom heat transfer.

- Adjust Settings | Set the heat press to 325°F with firm pressure (typically 60 psi) and a press time of 10–15 seconds. Always use a Teflon sheet or protective cover to shield the transfer and garment.

- Press and Peel | Once applied, peel the backing film hot for a seamless finish. For best results, use a smooth, even motion when peeling.

Caring for DTF Transfers: Maintenance and Longevity

To keep your DTF transfers looking their best, proper care is essential. After applying your transfer, always wash garments inside out in cold water to preserve the vibrant colors and sharp details.

Avoid using harsh detergents or bleach, as these can break down the adhesive and fade the print. When it comes to drying, opt for a low heat setting or air dry to prevent the transfer from cracking or peeling.

If ironing is necessary, use a low heat setting and place a piece of parchment paper or a teflon sheet over the transfer to protect it from direct heat. Regularly check your garments for loose threads or frayed edges, and address any issues promptly to extend the life of your custom apparel.

By following these simple maintenance tips, you’ll ensure that your DTF transfers remain bright, flexible, and durable—so your custom creations continue to impress, wash after wash.

Troubleshooting Common DTF Transfer Issues

Even with the highest quality DTF transfers, occasional issues can arise during the application process. If you notice that your transfer isn’t adhering properly, start by double-checking your heat press settings—ensure you’re using the recommended temperature and firm pressure for your specific transfer. Uneven pressure or incorrect temperature are common culprits behind transfers that peel or fail to bond.

If the transfer appears cracked or the colors aren’t as vibrant as expected, inspect the adhesive application and make sure the transfer material is compatible with your fabric. Proper alignment is also crucial; always position your transfer carefully before pressing to avoid misprints.

Should you encounter persistent problems, consult your heat press manual or reach out to customer support for expert guidance. By addressing these common issues promptly, you’ll maintain the quality and longevity of your DTF transfers, ensuring every press results in a flawless, professional finish.

Caring for DTF Transfers: Maintenance and Longevity

To keep your DTF transfers looking their best, proper care is essential. After applying your transfer, always wash garments inside out in cold water to preserve the vibrant colors and sharp details.

Avoid using harsh detergents or bleach, as these can break down the adhesive and fade the print. When it comes to drying, opt for a low heat setting or air dry to prevent the transfer from cracking or peeling.

If ironing is necessary, use a low heat setting and place a piece of parchment paper or a teflon sheet over the transfer to protect it from direct heat. Regularly check your garments for loose threads or frayed edges, and address any issues promptly to extend the life of your custom apparel.

By following these simple maintenance tips, you’ll ensure that your DTF transfers remain bright, flexible, and durable—so your custom creations continue to impress, wash after wash.

Troubleshooting Common DTF Transfer Issues

Even with the highest quality DTF transfers, occasional issues can arise during the application process.

If you notice that your transfer isn’t adhering properly, start by double-checking your heat press settings—ensure you’re using the recommended temperature and firm pressure for your specific transfer. Uneven pressure or incorrect temperature are common culprits behind transfers that peel or fail to bond.

If the transfer appears cracked or the colors aren’t as vibrant as expected, inspect the adhesive application and make sure the transfer material is compatible with your fabric. Proper alignment is also crucial; always position your transfer carefully before pressing to avoid misprints.

Should you encounter persistent problems, consult your heat press manual or reach out to customer support for expert guidance. By addressing these common issues promptly, you’ll maintain the quality and longevity of your DTF transfers, ensuring every press results in a flawless, professional finish.

Your FAQs About DTF Transfers Answered

- What file types are accepted for custom transfers? PDF and PNG files with transparent backgrounds.

- What’s the ideal temperature for heat pressing? 325°F with firm pressure.

- How long do DTF transfers last? With proper care, they can last as long as the garment itself.

- Do you offer bulk discounts? Absolutely! Contact us for pricing on large orders.

- Can I get a sample pack? Yes! We offer free samples for new customers.

Create High-Quality Custom DTF Transfers & Apparel with Limitless Transfers

DTF transfers have unlocked endless possibilities for creatives and businesses alike, and no one does it better than Limitless Transfers. With free shipping, fast turnaround times, and hot peel, vibrant transfers, we’re here to make your custom apparel dreams come true.

Start Your Custom Transfer Order Today!

Learn More About DTF Transfers

Direct-to-Film (DTF) printing has quickly become one of the most versatile and game-changing methods in custom apparel decoration. Whether you’re new to the scene or want to level up your knowledge, these trusted resources will help you dive deeper into DTF transfers—how they work, how to use them, and how to get the best results.

Top Resources for Learning About DTF Transfers

- The Truth About Direct to Film Printing – A helpful beginner’s guide from industry giant Stahls’.

- DTF vs. DTG: What’s the Difference? – A side-by-side breakdown of two major printing methods.

- What is DTF? – Supacolor walks through the full DTF process.

- DTF Transfer Heat Press Guide – Instructions and heat settings for the best press.

- YouTube: How to Use DTF Transfers – Video tutorials from top creators and printers.

- Choosing the Right Film & Ink – A breakdown of materials and tools needed.

- DTF Transfer Care Instructions – How to wash and care for DTF-printed garments.

- Common DTF Printing Mistakes & Fixes – Troubleshooting help for clean, vibrant transfers.

- DTF Trends & Future Outlook – Industry insights on where DTF is headed next.

Ready to start printing? Order your free sample from Limitless Transfers and see why more creators are switching to DTF for bold, long-lasting designs.