What is a DTF Transfer?

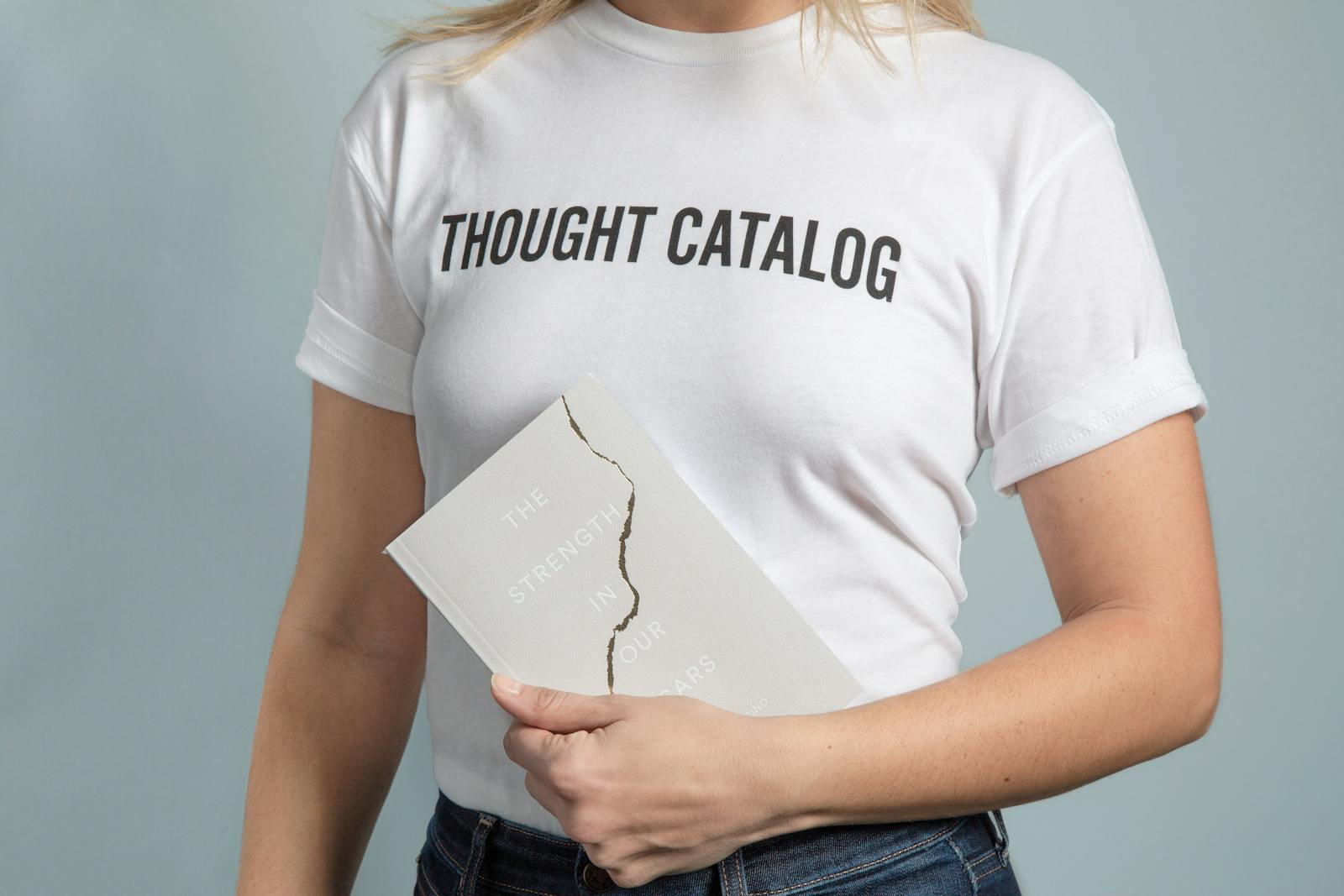

Custom printing has transformed the way we create and personalize garments. One breakthrough technique changing the game is DTF printing (direct to film dtf), a method that creates full-color transfers suitable for various garments and materials.

Whether you’re a business owner, designer, or printing hobbyist, understanding DTF transfers is essential for maximizing creativity and efficiency in custom garment decoration.

This guide breaks down everything you need to know about DTF transfers—from what they are to their benefits, process, and tips for achieving the best results. By the end, you’ll discover how DTF printing could revolutionize how you approach apparel decoration.

Introduction to DTF Transfers

DTF transfers are a revolutionary printing method that has gained significant popularity in recent times, offering a cost-effective alternative to other printing methods like DTG and sublimation.

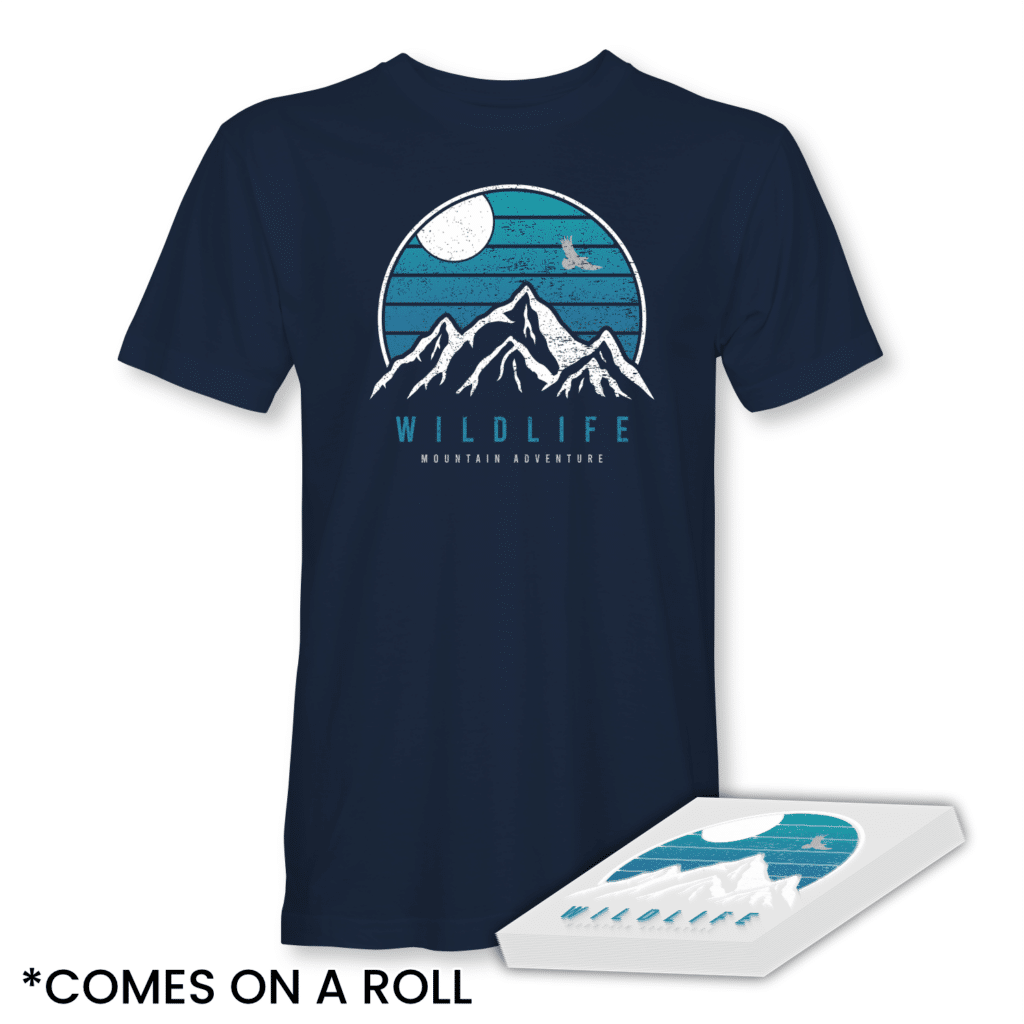

These transfers are a type of full-color transfer that can be applied to various garments, materials, and substrates, including cotton, polyester, and blends, using a heat press machine or even a household iron.

DTF stands for “Direct to Film,” which refers to the process of printing designs directly onto a special film. This technique improves the speed and ease of application, making it an ideal choice for custom printing enthusiasts and businesses.

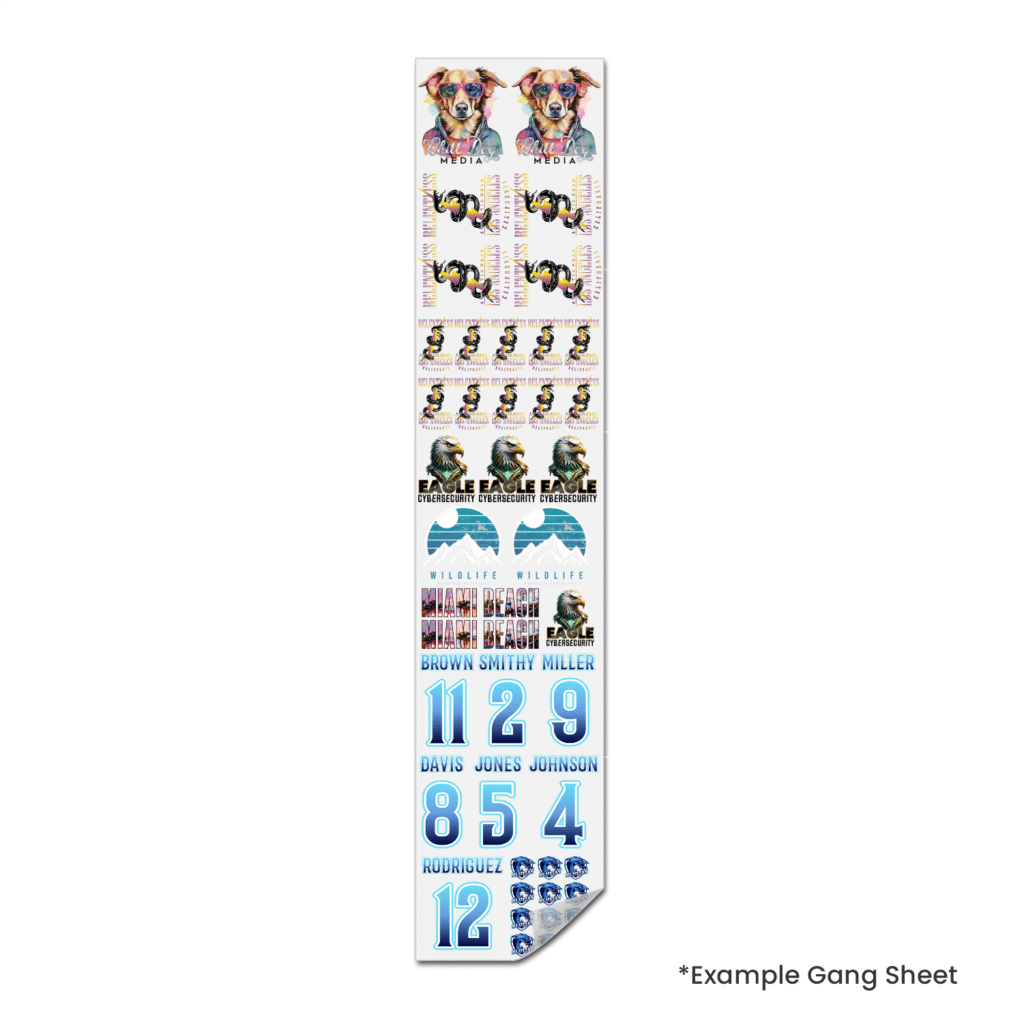

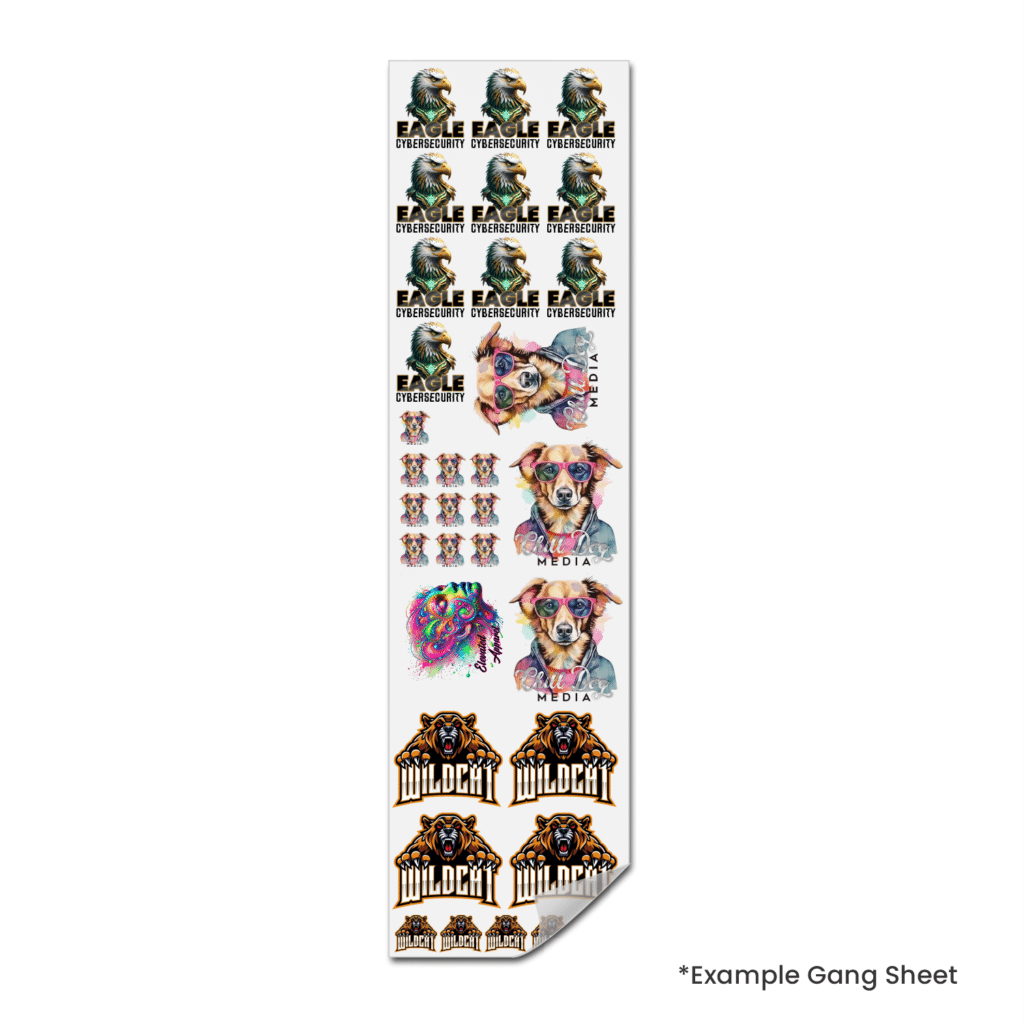

The process involves printing your design onto a special film, applying adhesive powder, curing the design, and then transferring it onto the fabric using heat and pressure.

One of the standout features of DTF transfers is their durability. These prints are highly durable and washable, withstanding over 60 washes without fading. This makes them a popular choice for athletic wear, team uniforms, and other custom garments that require long-lasting, vibrant designs.

Whether you’re a small business owner or a hobbyist, DTF transfers offer a versatile and efficient solution for your custom printing needs.

What is a DTF Transfer?

DTF, or “Direct to Film,” is a modern printing method that allows you to transfer vibrant, high-quality designs directly onto fabrics and other materials using a printed film.

Custom DTF transfers significantly enhance the quality and uniqueness of the printing process, allowing businesses to differentiate themselves from competitors and produce superior results in their projects.

Unlike traditional printing methods like screen printing or DTG printing (Direct to Garment), DTF transfers are extremely versatile. They can be applied to light and dark fabrics, cotton, polyester, nylon, and other materials. A heat press machine or even a household iron is all you need to complete the transfer.

Key Features of DTF Transfers:

Full-Color Designs:

DTF transfers support incredibly detailed, vibrant, and multicolored images, making them suitable for complex designs.

Compatible with Various Fabrics:

Whether you’re printing on t-shirts, athletic wear, tote bags, or other items, DTF transfers work with virtually any fabric.

Cost-Effective for Small Batches:

Perfect for printing small orders or samples due to their speedy, flexible process.

Durable Prints:

Do DTF transfers withstand over 60 washes without fading, making them highly durable for everyday use with proper care.

With these capabilities, DTF printing is quickly becoming an industry favorite among custom printing businesses and apparel decorators.

Benefits and Applications of DTF Printing

Why Choose DTF Printing?

DTF offers a variety of advantages over other printing methods, making it an ideal choice for many applications. Here’s why:

- Durability: Prints created with DTF transfers are exceptionally durable and retain their vibrancy for months, even with frequent washing.

- Versatility: DTF is compatible with various materials and surfaces—not just cotton or polyester. It also works on nylon and blends, making it flexible for diverse projects.

- Ease of Use: With minimal learning and basic equipment like a heat press machine, many businesses and enthusiasts can get started with DTF printing right away.

- Cost-Effective Solution: DTF transfers are suitable for small batch printing, making it accessible for startups and small businesses.

- Unlimited Applications: Use DTF transfers to create custom t-shirts, athletic uniforms, tote bags, caps, and even accessories. They cater to personalized gifts and niche merchandise.

By combining flexibility, quality, and affordability, DTF transfers deliver impressive results no matter the application. Unlike traditional techniques like heat transfer paper, DTF offers superior heat transfer capabilities, ensuring high-quality prints across different materials.

Equipment Needed for DTF Printing

To produce high-quality custom DTF transfers, you’ll need a few essential pieces of equipment. First and foremost, a specialist DTF printer is required or a Direct to Film (DTF) transfer supplier, like Limitless Transfers. These printers are designed to handle the unique requirements of DTF printing, ensuring that your designs are vibrant and detailed. You can also use a converted desktop inkjet printer or a laser printer for this purpose.

Next, you’ll need DTF transfer films, including PET films, which are used to print your designs. These films are then transferred onto the desired surface using heat and pressure. Adhesive powder, also known as hot melt powder, is another crucial component. This powder binds the color pigments to the transfer, ensuring a durable and long-lasting print.

DTF inks, including CMYK, white, and black inks, are used to create your designs. These inks are specially formulated for DTF printing, providing vibrant and opaque colors that stand out on both light and dark fabrics. An automatic powder shaker is also essential for removing excess powder and applying it evenly to the transfer, ensuring a smooth and even finish.

By investing in the right equipment, you can ensure that your DTF prints are of the highest quality, providing your customers with durable and vibrant designs.

Materials for DTF Transfers

One of the key advantages of DTF transfers is their versatility. They can be applied to a wide range of materials, including fabrics, papers, and plastics, making them a versatile printing method. Whether you’re working with cotton, polyester, or blends, DTF transfers can handle it all without the need for pre-treatment.

DTF transfers are suitable for various applications, including apparel, accessories, and promotional items. You can use them to create custom t-shirts, tote bags, and other custom garments. They can also be used to print on various substrates, including paper, plastic, and metal, making them a popular choice for custom printing enthusiasts and businesses.

Another significant benefit of DTF transfers is their flexibility. They are incredibly flexible and can be used for small batch printing, making them an ideal choice for businesses and individuals who need to print small quantities. This flexibility allows you to experiment with different designs and materials, providing endless possibilities for your custom printing projects.

Color Options for DTF Transfers

DTF transfers offer a wide range of color options, making them ideal for creating vibrant and long-lasting prints. They can handle both white and CMYK colors, allowing you to produce a wide range of colors, including neon colors. This capability makes DTF transfers perfect for creating intricate designs and patterns.

One of the standout features of DTF transfers is their ability to print on light or dark-colored garments and materials without the need for pre-treatment. This makes them a popular choice for custom printing enthusiasts and businesses looking to create high-quality designs with detailed designs and vibrant colors.

DTF transfers are also a cost-effective alternative to other printing methods, such as screen printing. They can be used to print on various fabrics, including cotton, polyester, and blends, providing a versatile and affordable solution for your custom printing needs.

Whether you’re creating athletic wear, team uniforms, or other custom garments, DTF transfers offer unmatched color quality and durability.

By leveraging the color capabilities of DTF transfers, you can create stunning, high-quality designs that stand out and last.

The DTF Printing Process Explained

How Does DTF Printing Work?

The DTF printing technique involves several simple but crucial steps to create high-quality custom prints. This revolutionary method in the context of transfers has transformed the industry. Here’s how it works step-by-step:

Step 1: Printing the Design

Use a DTF printer (or converted inkjet printer) to print your design on a specialized DTF film. Utilizing RIP software is crucial in this process as it significantly influences color performance and print quality. This process uses colored pigments and a white ink layer to ensure vibrant and opaque designs that work on dark fabrics.

Step 2: Applying Adhesive

After printing, the hot melt adhesive powder is applied to the ink. This powder essentially “sticks” the design to the film.

Step 3: Curing the Design

The printed film is placed in a curing oven or under a heat press, which are examples of the specialized equipment necessary to bond the adhesive powder to the design.

Step 4: Transferring to Fabric

Applying DTF transfers involves several key steps to ensure a successful outcome. Simply place the transfer film onto your fabric, image-side down. Use a heat press machine (or household iron) to firmly press the design onto the fabric using controlled temperature, pressure, and timing.

Step 5: Peeling Off the Film

Once cooled, gently peel off the film to reveal your vibrant and long-lasting design!

This printing process stands out for its simplicity and ability to handle both small batch orders and intricate designs seamlessly.

Troubleshooting and Maintenance for DTF Transfers

Like any printing method, DTF transfers require regular maintenance and troubleshooting to ensure consistent results.

Common Challenges:

- Fading or Peeling Prints: Ensure the printed image receives proper heat, pressure, and curing times during the transfer process to maintain durability and adherence.

- Excess Powder Residue: Excessive adhesive powder can lead to poor print outcomes. Always apply the correct amount.

- Poor Print Alignment: Align the DTF film carefully on your fabric before pressing.

Maintenance Tips:

- Regularly clean and calibrate your heat press machine.

- Use high-quality DTF film, adhesive powders, and inks to avoid issues with consistency and durability.

By following best practices, you’ll achieve optimal results and wow your customers with premium-quality prints.

Tips and Best Practices for DTF Printing Success

To elevate your DTF printing process, keep these expert tips in mind:

Invest in Quality Supplies:

Choose durable DTF film, high-grade dtf powders, reliable colored pigments, and high-quality DTF printers for flawless prints.

Fine-Tune Your Equipment:

- Adjust your heat press settings.

- Regularly clean your equipment to maintain superior performance.

Cure Correctly:

Use a curing oven to ensure the ink bonds properly with the adhesive powder. This results in a durable DTF print, emphasizing the importance of proper curing to maintain the print’s quality over time.

Safety First:

Wear protective gloves and masks, and ensure proper ventilation when working with adhesives and powders.

Experiment with Designs:

Test new designs with small batch printing to refine your technique and achieve consistent quality.

By adopting these practices, apparel decorators can expand their creative possibilities and deliver high-quality products to their customers.

Find Resources and Join the Community

Connected communities are powerhouses of insight for anyone working in custom printing. Leverage these resources:

- Online Printing Communities: Join social media groups or forums to share techniques, troubleshoot, and learn from other apparel decorators.

- Educational Resources: Platforms offering courses or guides on DTF process basics help accelerate learning.

By staying connected, you’ll gain invaluable advice from seasoned professionals and elevate your craft.

How DTF Printing Revolutionizes Custom Apparel Decoration

DTF transfers make custom printing easier, faster, and more versatile than other methods, such as traditional printing techniques. Whether you’re personalizing t-shirts, creating team uniforms, or designing artistic tote bags, Direct to Film printing offers unmatched opportunities.

Still have questions about how DTF transfers can work for your business? Visit Limitless Transfers today to explore cutting-edge supplies and discover the solutions you need for your next printing project.