The printing industry has seen remarkable innovation over the past decade, with new technologies transforming how businesses approach custom apparel and merchandise. Among these breakthrough methods, DTF printing has emerged as a game-changing solution that’s captured the attention of entrepreneurs, fashion designers, and print shops worldwide.

DTF printing offers something many other printing methods struggle to deliver: true versatility without compromise. While screen printing requires large minimum orders and sublimation works only on specific fabrics, DTF bridges these gaps with exceptional flexibility and quality. DTF excels at creating vibrant and long-lasting prints, setting it apart from other printing technologies like DTG, screen printing, and sublimation. This comprehensive guide explores everything you need to know about DTF printing, from the basic technology to advanced business applications.

Whether you’re a small business owner exploring cost-effective printing options or an established designer seeking superior print quality, understanding DTF printing could revolutionize your approach to custom apparel production. DTF printing is transforming the printing business by enabling new business models and opportunities for growth. Let’s dive into this innovative printing technology and discover why it’s become the preferred choice for thousands of creative entrepreneurs.

Photo by Createasea on Unsplash

Introduction to Direct to Film Printing

Direct to Film (DTF) printing is a cutting-edge digital printing technology that is rapidly transforming the printing industry. Unlike traditional printing methods, DTF printing allows you to print designs directly onto a specially coated film, which can then be transferred onto a wide variety of substrates—including fabrics, plastics, and even metals—using a heat press machine. This direct to film (DTF) approach streamlines the printing process, making it easier than ever to achieve high quality prints with vibrant colors and intricate details.

One of the standout features of DTF printing technology is its remarkable versatility. Whether you’re producing custom t-shirts, promotional products, or unique merchandise, DTF printing offers consistent results across different materials and colors. The process is user-friendly and requires minimal setup, making it accessible for both small businesses and large-scale operations. By leveraging digital printing technology, DTF enables on-demand production, quick turnaround times, and the ability to create customized designs without the limitations of older printing methods.

The use of a heat press is central to the DTF printing method. After printing your design onto the film, the image is transferred onto the final product using a heat press machine, ensuring a durable and long-lasting finish. This makes DTF printing an ideal solution for custom t-shirt printing and other applications where print quality and durability are essential. As the demand for personalized and high quality prints continues to grow, direct to film DTF printing stands out as a reliable, efficient, and innovative choice for businesses and creators alike.

Photo by Corey Watson on Unsplash

What Does DTF Stand For?

DTF stands for Direct to Film printing, a digital printing technology that transfers designs from specially coated film directly onto fabric. This method represents a significant advancement in textile printing, combining the best aspects of traditional printing methods while eliminating many common limitations. With the DTF printing process explained, the steps include printing the design onto film, applying adhesive powder, and transferring the image onto fabric using heat.

The “direct to film” process involves printing designs onto a special PET (Polyethylene Terephthalate) film using water-based pigment inks, then applying hot melt adhesive powder to create a transfer that can be heat-pressed onto virtually any fabric. DTF printer ink is a specialized ink formulated for optimal results in DTF printer technology, ensuring vibrant colors and strong adhesion. This straightforward approach makes DTF printing accessible to businesses of all sizes while maintaining professional-grade results.

Unlike methods that require extensive setup or specialized equipment for each design, DTF printing streamlines the entire process. The technology works with modified desktop inkjet printers or purpose-built DTF printers, making it an attractive option for both small-scale operations and large production facilities. DTF printer technology enables the unique DTF process, which is known for its efficiency, versatility, and ability to produce high-quality prints on a wide range of textiles.

What is DTF in Gen Z?

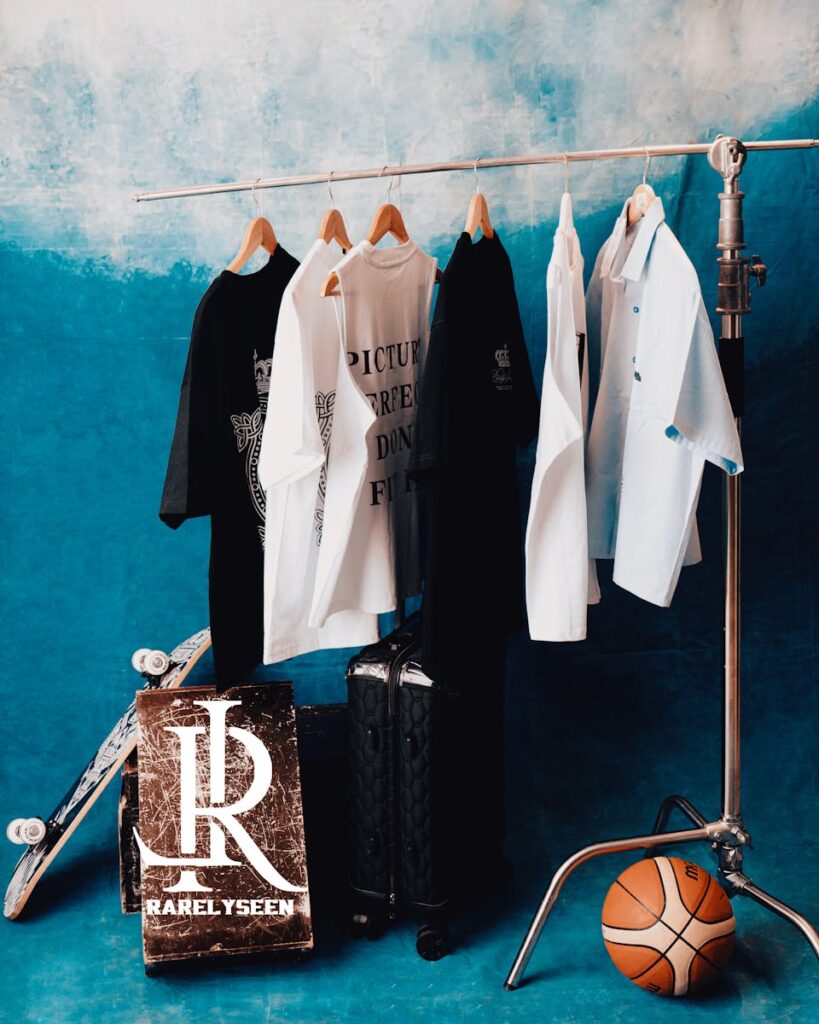

Gen Z has embraced DTF printing as a powerful tool for self-expression and entrepreneurship. This generation values authenticity, customization, and sustainable business practices—qualities that align perfectly with DTF printing capabilities.

Young entrepreneurs use DTF printing to launch custom apparel brands with minimal startup costs. The technology’s no-minimum-order capability allows Gen Z creators to test designs, build audiences, and scale businesses organically. Social media platforms like TikTok and Instagram have showcased countless success stories of young designers using DTF printing to turn creative ideas into profitable ventures.

The fashion-forward nature of Gen Z also drives demand for unique, personalized clothing. DTF printing enables on-demand customization, allowing young consumers to create one-of-a-kind pieces that reflect their individual style. This shift toward personalized fashion represents a departure from mass-produced clothing, giving Gen Z the tools to build distinctive wardrobes.

Furthermore, the environmental consciousness of this generation appreciates DTF printing’s waste-reduction benefits. Unlike screen printing, which requires extensive setup and often leads to overproduction, DTF printing produces only what’s needed, reducing textile waste and supporting more sustainable fashion practices.

Photo by Aj Collins Artistry on Pexels

What Exactly is a DTF Transfer?

A DTF transfer is a printed design on specialized film that includes both the artwork and an adhesive layer, ready for application to fabric. The transfer consists of three main components: the printed design using dtf ink and CMYK+W (Cyan, Magenta, Yellow, Black, and White) inks, the PET film substrate, and the cured hot melt adhesive powder.

The printed film showcases vibrant colors and fine details thanks to high-resolution printing capabilities up to 1440 dpi. The white ink layer serves as a foundation, ensuring bright colors appear vivid on both light and dark fabrics. This white ink layer is crucial for achieving color accuracy and preventing design elements from appearing washed out on colored garments. A dtf print is known for its resistance to cracking and fading, ensuring long-lasting results.

The adhesive powder, when properly cured, creates a flexible bond between the design and fabric. This adhesive maintains the transfer’s integrity through multiple wash cycles while preserving the soft hand feel that customers expect from quality apparel. Dtf prints are flexible and long-lasting, making them ideal for high-quality garment decoration. The combination of these elements results in a transfer that’s durable, vibrant, and comfortable to wear.

DTF transfers differ significantly from traditional heat transfer vinyl (HTV) or screen print transfers. While HTV requires cutting and weeding for each design element, DTF transfers print complete designs in a single process. Screen print transfers, though durable, typically require large minimum orders and longer production times. DTF transfers bridge these gaps, offering the detailed reproduction of digital printing with the durability of traditional methods. Dtf transfer films are specialized PET films used in the process to achieve high-quality transfers.

The film transfer process involves applying a design onto fabric by using a heat press to transfer the film-based design, and film transfers are valued for their high quality and durability in garment decoration. The use of transfer film is essential for achieving a successful bond between the design and the fabric. To print dtf transfers, follow the described process using dtf ink, dtf transfer films, adhesive powder, and a heat press for optimal results.

Photo by Photo By: Kaboompics.com on Pexels

The DTF Printing Process Explained | How DTF Printing Works

Step 1: Design Preparation

- Start by creating or selecting your design using graphic design software. It’s important to ensure your artwork is in a high-resolution format, as print resolution directly affects the sharpness and quality of the final transfer. Properly preparing your design will help avoid issues during printing and transfer.

The process begins with artwork preparation using graphic design software. Designs should be created in high resolution (300 dpi minimum) and saved in appropriate file formats. Print resolution is crucial for ensuring clear, vibrant DTF prints, as it directly affects the sharpness and quality of the final output.

Vector files work exceptionally well for DTF printing, as they maintain crisp edges at any size. The design must account for the white ink layer, which will be automatically generated by RIP software during printing.

Step 2: RIP Software Processing

RIP (Raster Image Processor) software optimizes the design for DTF printing. This software manages color profiles, ensures proper white ink placement, and adjusts printing parameters for optimal results. The RIP software converts the design into printable data that the DTF printer can process accurately.

Step 3: Film Printing

- Choose a suitable PET film designed for DTF printing. The film must be compatible with the inks and printer you plan to use.

- To print DTF, load the PET film into a specialized printer designed specifically for DTF processes. These specialized printers are required to handle the unique inks, film, and white ink layering needed for high-quality results. Use water based pigment ink and textile inks, as they are essential for producing vibrant, durable prints that bond well with fabrics.

The prepared design prints onto PET film using a desktop inkjet printer equipped with DTF inks or a purpose-built DTF printer. To print DTF, you need specialized printers that are designed to work with DTF printer ink, ensuring compatibility and high-quality results.

The printer applies CMYK colors first, followed by a white ink layer that provides opacity and color vibrancy. Water-based pigment ink and textile inks are used for optimal results, as they ensure excellent color reproduction, durability, and wash resistance.

Step 4: Adhesive Powder Application

- After printing, apply DTF powder evenly to the wet ink on the film. Shake off the excess powder to ensure only the printed areas are covered.

Immediately after printing, hot melt adhesive powder is applied to the wet ink surface. This powder adheres to the ink while creating the bonding agent necessary for fabric transfer. Excess powder is removed, leaving only the powder that bonds with the printed design.

Step 5: Powder Curing

- Cure the powder by heating the film, which melts the powder and bonds it to the ink. This step is crucial for ensuring the transfer adheres properly to the fabric.

The powder-coated transfer passes through a curing unit or heat press to melt and set the adhesive. This process typically requires temperatures around 300-320°F (150-160°C) for 15-20 seconds. Proper curing ensures the adhesive forms a strong, flexible bond that won’t crack or peel.

Step 6: Heat Press Application

- Place the cured film onto the garment and use a heat press to transfer the design. Once cooled, peel off the film to reveal the finished product. A t shirt printed using DTF will have vibrant colors, excellent detail, and a soft feel.

The cured transfer is positioned on the fabric and pressed using a heat press machine. The heat and pressure activate the adhesive, bonding the design permanently to the fabric. Most DTF transfers are “hot peel,” meaning they can be removed immediately after pressing, speeding up production.

A t shirt printed using the DTF film transfer process, where the design is first printed onto a transfer film and then applied to the fabric, results in a high-quality and durable finish that stands up well to repeated washing and wear.

Photo by DISPLACED BY DESIGN CLOTHING on Pexels

How to Use a Direct to Film Printer

Using a Direct to Film (DTF) printer is a straightforward process that combines modern printing technology with practical techniques to deliver outstanding results. The journey begins with creating your design using graphic design software, ensuring your artwork is optimized for the DTF printing process.

Once your design is ready, it’s printed onto a special DTF film using a DTF printer, which is engineered to handle the unique requirements of direct to film DTF printing.

After the design is printed, the next step involves applying a layer of hot melt adhesive powder to the wet ink on the printed film. This adhesive powder is crucial, as it enables the ink to bond securely to the substrate during the transfer process. The film, now coated with adhesive, is gently shaken to remove any excess powder and then cured—usually by passing it through a curing unit or briefly using a heat press—to activate the adhesive.

With the adhesive set, the printed film is carefully positioned onto the desired substrate, such as a t-shirt or other fabric. Using a heat press machine, heat and pressure are applied to the film, causing the adhesive to melt and permanently bond the design to the substrate. After pressing, the film is peeled away, revealing a vibrant, durable print that stands up to repeated washing and wear.

This efficient workflow—combining a DTF printer, DTF film, hot melt adhesive powder, and a heat press—makes DTF printing accessible to both beginners and experienced professionals. By mastering these steps, you can produce high quality, customized prints with minimal effort, expanding your creative possibilities and business potential.

Photo by Sebastiaan Stam on Pexels

Film Printing and Its Applications

Film printing, often referred to as transfer printing, is a versatile and widely used printing method that involves printing designs onto a film before transferring them onto a final substrate. This approach has become increasingly popular thanks to advancements in DTF printing technology, which have made it easier and more affordable to achieve professional results.

The primary advantage of film printing lies in its ability to deliver exceptional print quality and durability. Whether you’re creating custom t-shirts, promotional products, signage, or advertising materials, film printing ensures that your designs are reproduced with sharp details and vibrant colors.

The flexibility of this printing method allows for customization across a wide range of products, making it a favorite for businesses and individuals looking to offer unique, personalized items.

With the rise of DTF printing, film printing has reached new heights in terms of accessibility and performance. DTF printing technology streamlines the process, allowing for quick turnaround times and consistent results, even on complex or multi-color designs. This has opened up new opportunities for custom t-shirt printing, small-batch production, and creative projects that demand both quality and versatility.

In summary, film printing—especially when powered by modern DTF printing methods—offers a powerful solution for anyone seeking high print quality, durability, and the ability to bring creative visions to life on a variety of substrates. Whether for personal use or commercial applications, transfer printing continues to be a cornerstone of the printing industry.

Photo by Danang Wicaksono on Pexels

DTF Printing vs. Other Printing Methods | Which is Best For Your Printing Business?

Understanding how DTF printing compares to other popular methods helps businesses choose the right technology for their needs. In this article, we compare two printing methods—DTF and white toner printing—to highlight their differences in process, cost, and results. Each method offers distinct advantages and limitations among modern printing technologies, and DTF stands out for its versatility and efficiency.

DTF vs. Screen Printing

Screen printing remains the gold standard for large-volume production, offering excellent durability and cost-effectiveness for orders exceeding 144 pieces. However, screen printing requires significant setup time, specialized screens for each color, and skilled operators. Complex designs with multiple colors can become prohibitively expensive.

DTF printing excels in short-run production and complex designs. With no setup fees or minimum orders, DTF enables on-demand printing that screen printing cannot match. The digital nature of DTF allows for intricate details and unlimited colors without additional costs.

However, screen printing typically offers lower per-unit costs for very large orders. Printing costs can vary significantly between DTF and screen printing, especially depending on order size, design complexity, and production scale.

DTF vs. Sublimation

Sublimation printing produces vibrant, permanent prints by converting solid ink into gas that bonds with polyester fibers. This method works exceptionally well on light-colored polyester garments and polymer-coated substrates. However, sublimation is limited to specific fabric types and doesn’t work effectively on cotton or dark-colored garments.

Additionally, sublimation can sometimes create subliminal printing effects, where the design appears more subtle or understated compared to the bold, vivid results of DTF.

DTF printing offers superior fabric versatility, working on cotton, polyester, blends, and even non-textile materials like leather and canvas. While sublimation may offer slightly better wash durability on polyester, DTF provides the flexibility to print on any fabric type with excellent durability.

DTF vs. Direct to Garment (DTG) Printing

DTG printing applies water-based inks directly to fabric using modified inkjet printers. This method produces soft, breathable prints that feel natural on cotton garments.

However, DTG requires pretreatment for dark garments, has limitations on certain fabric types, and can be slower for production. In terms of durability and flexibility, dtg prints are generally less resistant to cracking and peeling over time compared to DTF prints, which are known for their superior longevity and elasticity.

DTF printing offers faster production speeds and works on more fabric types without pretreatment. The transfer process allows for consistent results regardless of fabric color or composition. While DTG may feel slightly softer on cotton, DTF provides more consistent results across different fabric types.

Additionally, printing costs for DTG can be higher, especially for small runs or certain fabrics, whereas DTF printing is often more cost-effective for a wider range of materials and production scales.

DTF vs. White Toner Laser Printing

White toner laser printing uses toner instead of ink to create transfers for light and dark fabrics. This method offers good durability and works well for certain applications. However, white toner systems can be expensive to operate, and the prints may feel thicker than other methods. White toner printing also requires a laser printer and cut transfer papers, which add to the overall cost and process complexity compared to other printing methods.

DTF printing typically offers better color vibrancy and a softer hand feel compared to white toner methods. The ink-based system provides more natural-looking colors and better integration with fabric fibers. Additionally, DTF printers generally have lower operating costs and easier maintenance requirements.

Photo by Wendel Natan on Pexels

Advantages of DTF Printing

DTF printing offers numerous advantages that make it attractive for businesses of all sizes. These benefits explain why many print shops and entrepreneurs are adopting this technology.

Versatility Across Fabrics

DTF printing works on virtually any fabric type, from 100% cotton to polyester blends, tri-blends, and even non-textile materials. This versatility eliminates the need for multiple printing methods, simplifying inventory management and expanding product offerings. Businesses can accept orders for various garment types without worrying about compatibility issues.

No Minimum Orders

Unlike screen printing, which requires minimum orders to be cost-effective, DTF printing offers economical single-piece production. This flexibility enables businesses to offer sample products, test new designs, and fulfill small custom orders profitably. The no-minimum approach also reduces inventory risk and allows for more responsive customer service.

High Print Quality

DTF printing produces sharp, detailed prints with excellent color accuracy. The high resolution capabilities (up to 1440 dpi) ensure fine details reproduce clearly, while the wide color gamut captures vibrant, true-to-life colors. The white ink layer provides excellent opacity, ensuring colors appear bright on both light and dark fabrics.

Cost-Effective for Small to Medium Runs

DTF printing offers an excellent cost-per-print ratio for orders ranging from single pieces to several hundred units. Without setup fees or screen costs, the pricing structure remains consistent regardless of order size. This predictable pricing helps businesses maintain healthy profit margins while offering competitive pricing to customers.

Ease of Use

The DTF printing process is relatively straightforward, requiring minimal training for operators. The digital workflow eliminates many variables present in traditional printing methods, leading to more consistent results. Hot peel transfers speed up production by eliminating wait times, while the simple heat press application requires minimal skill to achieve professional results.

Excellent Durability

Properly produced DTF transfers withstand numerous wash cycles without significant fading or cracking. The water-based pigment inks and flexible adhesive system maintain print integrity through normal wear and washing. This durability matches or exceeds many traditional printing methods while offering superior versatility.

Photo by Kristina Paukshtite on Pexels

Who Can Benefit from DTF Printing?

DTF printing serves a diverse range of users, from individual creators to established businesses. Understanding these audiences helps identify opportunities for DTF adoption.

Small Business Owners

Entrepreneurs launching custom apparel brands benefit from DTF printing’s low barrier to entry. The technology enables product testing, market validation, and gradual scaling without significant upfront investment. Small businesses can offer diverse product lines without inventory risk, responding quickly to market trends and customer demands.

Fashion Designers

Independent designers use DTF printing to bring creative visions to life without traditional manufacturing constraints. The technology supports complex designs, unlimited colors, and various fabric types, enabling designers to focus on creativity rather than production limitations. Sample production becomes affordable, facilitating design development and client presentations.

Print Shops and Service Providers

Established print shops add DTF capabilities to expand service offerings and improve profitability. The technology complements existing services while opening new market segments. Print shops can offer faster turnaround times, accept smaller orders, and provide solutions for previously challenging applications.

E-commerce Entrepreneurs

Online sellers leverage DTF printing for on-demand production, eliminating inventory investment and storage costs. The technology enables personalization, seasonal designs, and trend-responsive products that traditional methods cannot support efficiently. Print-on-demand models become viable with DTF’s cost structure and quality.

Corporate and Promotional Products

Companies needing branded merchandise appreciate DTF printing’s flexibility and quick turnaround. The technology supports employee uniforms, promotional items, and event merchandise without minimum order constraints. Corporate clients benefit from consistent branding across various garment types and colors.

Limitless Transfers: Your DTF Solution

Limitless Transfers stands as the industry leader in DTF printing services, earning back-to-back first place awards for quality in 2024 and 2025. Our commitment to excellence shows in every aspect of our service, from cutting-edge printing technology to exceptional customer support.

Award-Winning Quality

Our recognition as the #1 DTF printing supplier reflects our dedication to superior print quality and customer satisfaction. We utilize state-of-the-art CMYK+W DTF printers combined with extensively researched ICC profiles, premium films, and high-quality inks. This combination ensures exceptional color accuracy, fine detail reproduction, and vibrant results that exceed industry standards.

Unmatched Convenience

Limitless Transfers eliminates common barriers to DTF printing with our no-minimum, no-setup-fee approach. Free UPS Ground shipping on orders over $50 adds value while supporting business growth. Same-day shipping on orders placed by noon EST ensures rapid turnaround for urgent projects, helping customers meet tight deadlines.

True Hot Peel Technology

Our hot peel transfers enable immediate removal after heat pressing, dramatically increasing production speed. This technology advantage allows high-volume production without waiting periods, making large orders more manageable and profitable. The hot peel feature also indicates proper curing, ensuring consistent quality across all transfers.

Comprehensive Business Support

Beyond printing services, Limitless Transfers serves as a complete resource for DTF printing needs. Our equipment and supplies section provides everything from heat presses to application tools, supporting businesses at every stage of growth. This one-stop-shop approach simplifies vendor management while ensuring compatibility across all components.

User-Friendly Ordering

Our innovative ordering system accommodates different skill levels and business models. The gang sheet builder enables easy design arrangement for maximum efficiency, while our file uploader accepts ready-to-print artwork. Individual transfer ordering by size simplifies the process for straightforward projects, ensuring every customer finds their ideal solution.

Photo by Photo By: Kaboompics.com on Pexels

How to Order DTF Transfers from Limitless Transfers

Ordering from Limitless Transfers is designed to be simple and efficient, accommodating various business needs and technical skill levels. Our three ordering methods ensure every customer finds the perfect solution for their requirements.

Method 1: Submit Ready-to-Print Gang Sheet Files

For customers with graphic design experience, uploading ready-to-print gang sheet files offers the best pricing. This method accepts PDF or PNG files designed at 22.5 inches wide by any required length. Vector files and CMYK color mode provide the most accurate color reproduction, while proper file preparation ensures optimal print quality.

Method 2: Use Our Gang Sheet Builder

Our intuitive gang sheet builder allows customers to create optimized layouts directly on our website. This tool accepts PNG files and features an auto-build function that maximizes material usage. The builder provides better pricing than individual transfers while eliminating the need for external design software.

Method 3: Order DTF Transfers by Size

The simplest ordering method allows customers to select transfer sizes and upload individual designs. This straightforward approach works well for simple projects and customers new to DTF printing. Clear pricing structure and simple file requirements make this method accessible to all skill levels.

Order Process

- Select Your Method: Choose the ordering approach that best fits your needs and skill level

- Upload Your Artwork: Submit designs in the appropriate file format for your chosen method

- Review and Confirm: Verify design placement, quantities, and specifications before finalizing

- Process Payment: Complete your order using secure payment processing

- Track Your Order: Monitor production progress and shipping updates through our system

Tips for Successful DTF Printing

Achieving optimal results with DTF printing requires attention to several key factors. These tips help ensure consistent quality and customer satisfaction.

Artwork Preparation

Design files should be created at 300 dpi minimum resolution for sharp, detailed prints. Vector artwork scales perfectly and maintains crisp edges at any size. When designing for DTF, consider that the white ink layer will be automatically generated, so transparent backgrounds work best for complex designs.

Color mode affects final results significantly. CMYK files generally produce more predictable colors than RGB, especially when using ICC profiles. Avoid pure black text or fine lines, as these may appear muddy. Instead, use rich black (C:30, M:30, Y:30, K:100) for better density and clarity.

Heat Press Settings

Proper heat press settings ensure strong adhesion and longevity. Most DTF transfers require temperatures between 300-320°F (150-160°C) with medium pressure for 15-20 seconds. Preheat garments to remove moisture and wrinkles before applying transfers. Even pressure distribution across the entire transfer area prevents adhesion problems.

Fabric Selection

While DTF works on most fabrics, some perform better than others. Cotton and cotton blends provide excellent results with good wash durability. Polyester works well but may require slightly different time and temperature settings. Avoid heavily textured fabrics that prevent even contact with the transfer surface.

Application Techniques

Position transfers carefully before pressing, as repositioning can damage the adhesive. Use a protective sheet to prevent direct contact between the heat press and transfer. Apply firm, even pressure across the entire transfer area. Hot peel transfers should be removed immediately while still warm for best results.

Care Instructions

Proper care extends transfer life significantly. Wash garments inside out in cold water with mild detergent. Avoid bleach, fabric softeners, and high-temperature drying. Air drying or low-heat tumble drying preserves transfer integrity. These simple care instructions help maintain vibrant colors and prevent premature wear.

Photo by Ike louie Natividad on Pexels

Transform Your Business with DTF Printing

DTF printing represents more than just another printing method—it’s a gateway to business transformation and creative freedom. The technology’s unique combination of versatility, quality, and accessibility opens doors that traditional printing methods keep closed.

The success stories emerging from DTF adoption span every industry segment. Small business owners launch profitable ventures with minimal investment. Established companies expand service offerings and improve margins. Creative professionals bring ambitious projects to life without compromise. This widespread adoption reflects DTF printing’s ability to solve real business challenges while enabling growth.

As the printing industry continues evolving, DTF technology positions businesses for future success. The method’s adaptability ensures relevance across changing market conditions, while its cost structure supports sustainable growth. Companies investing in DTF capabilities today build competitive advantages that compound over time.

The choice of DTF printing partner significantly impacts success outcomes. Quality, service, and support determine whether DTF implementation enhances or hinders business growth. Limitless Transfers combines award-winning quality with comprehensive support, ensuring every customer achieves their goals.

Frequently Asked Questions About DTF Printing

What types of fabrics can DTF be used on?

DTF printing works on virtually any fabric type, including 100% cotton, polyester, cotton/polyester blends, tri-blends, nylon, and even non-textile materials like leather, canvas, and wood. This versatility makes DTF ideal for businesses serving diverse markets or customers wanting to expand their product offerings.

How long do DTF transfers last?

Properly applied DTF transfers withstand numerous wash cycles without significant fading or cracking. With correct application and care, transfers can last 50+ washes while maintaining good appearance. Factors affecting longevity include fabric type, wash temperature, detergent choice, and drying method.

Can DTF transfers be applied to dark fabrics?

Yes, DTF transfers work excellently on dark fabrics thanks to the white ink layer that provides opacity. This white layer ensures colors appear vibrant and true-to-life regardless of fabric color, unlike some other printing methods that struggle with dark backgrounds.

What equipment is needed for DTF printing?

DTF printing requires a modified inkjet printer or purpose-built DTF printer, RIP software, DTF inks, PET film, hot melt adhesive powder, a curing unit or conveyor dryer, and a heat press. While the initial investment is significant, many businesses find the versatility and quality justify the cost.

How does DTF printing cost compare to other methods?

DTF printing offers excellent cost-efficiency when compared to other printing techniques, particularly for small to medium-sized runs. Unlike screen printing, which requires creating individual screens for each design, DTF printing eliminates this step, saving both time and expense. The upfront costs for specialized equipment may be higher, but the lower material and labor costs per print make it a competitive choice in the long run, especially for detailed, multi-color designs. This makes DTF printing an attractive option for businesses seeking high-quality results without the overhead associated with traditional methods.

Learn More About DTF Transfers

Direct-to-Film (DTF) printing is revolutionizing the world of custom apparel. Whether you’re just getting started or looking to scale your DTF business, these resources offer valuable insights:

- What Is DTF Printing?

- Beginner’s Guide to DTF Transfers

- DTF Printing vs. Sublimation: Key Differences

- How to Apply a DTF Transfer Correctly

- Best Heat Press Settings for DTF Transfers

- DTF Supplies & Equipment Checklist

- Tips to Get Crisp, Long-Lasting DTF Prints

- Common DTF Printing Mistakes & Fixes

- How DTF Printing Works (Video Tutorial)