Are you considering trying direct to film (DTF) transfers?

What Makes DTF Printing a Game Changer

Printing technology has come a long way. From messy ink blocks to complex screen setups, the methods for putting designs on apparel have constantly evolved. Now, a new innovation is making waves for its quality, versatility, and efficiency: Direct to Film (DTF) printing. This technology is quickly becoming the go-to choice for creators and businesses in the apparel world.

So, what is DTF printing? It’s a process that allows you to print a design onto a special film, which is then transferred to any garment or fabric using a heat press. It delivers vibrant, high-quality results without the limitations of older methods. At Limitless Transfers, we’ve seen firsthand how direct to film printing empowers creators. From small Etsy shops to large established brands, DTF helps everyone produce professional, durable results with far less hassle.

What Is Direct to Film (DTF) Printing?

Let’s break down how direct to film (DTF) works. The process is straightforward but powerful. First, a design is printed onto a special DTF film using specialized water-based DTF inks. A layer of white ink is printed behind the color design, which makes the colors pop on any garment.

Next, a fine adhesive powder is applied to the wet ink. This DTF powder is what bonds the design to the fabric. After shaking off the excess, the film is cured with heat, which melts the powder into an even adhesive layer. Finally, the design is placed on the garment and pressed with heat. The result is a vibrant, flexible, and durable print.

Compared to traditional methods, DTF offers incredible versatility. Screen printing often requires separate screens for each color, making complex designs expensive and time-consuming. Direct-to-garment (DTG) printing is great for cotton but struggles with polyester and other materials. DTF printing bridges this gap, offering full-color, high-quality prints on a massive range of fabrics without extensive setup.

Why Businesses Are Switching to DTF

The shift toward DTF is driven by major advantages in time, cost, and creative freedom. DTF printing saves time by removing the tedious setup associated with screen printing. There’s no need to create screens or mix inks for every color in a design. This efficiency directly translates to lower costs, especially for small or multi-color orders.

One of the biggest benefits is the lack of order minimums. With DTF transfers, you can print a single shirt to test a new design just as easily as you can produce a thousand for a large event. This flexibility, combined with fast turnarounds, is perfect for businesses that need to be agile. You can scale from one-offs to large orders without changing your process.

Furthermore, innovations like hot peel transfers dramatically increase production speed. A hot peel film allows you to peel the transfer sheet away immediately after pressing, unlike cold peel, which requires waiting for the transfer to cool. This lets you move from one garment to the next in seconds, boosting your output and getting products to customers faster. The durable, high-quality finish with fine detail keeps businesses competitive.

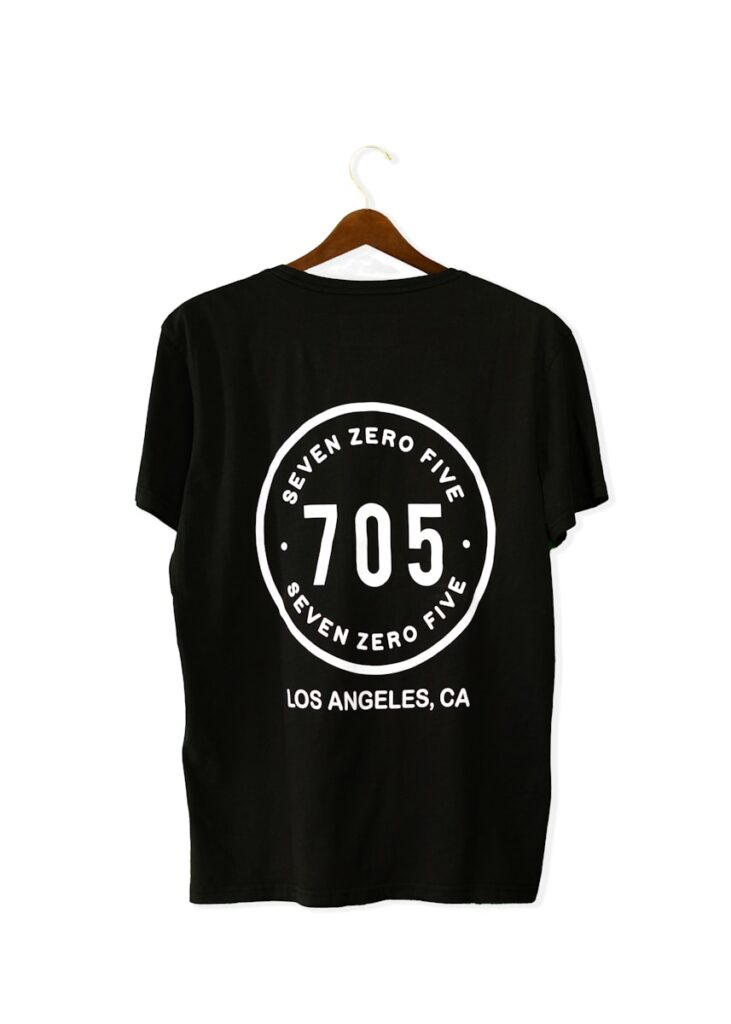

Photo by Ryan Hoffman on Unsplash

Materials That Work with DTF

DTF printing stands out for its incredible material compatibility. While other printing methods are limited to specific fabric types, DTF transfers work on almost anything. You can apply designs to 100% cotton, polyester, and various poly-cotton blends with ease. But it doesn’t stop there. DTF also works beautifully on nylon, leather, canvas, denim, and even hard surfaces like wood.

The secret lies in the combination of the adhesive powder and the specialized PET film. The adhesive creates a strong bond that adheres to virtually any surface, whether it’s a light or dark color garment. Because the design is first printed onto the film and then transferred, the fabric’s texture and color don’t interfere with the print quality. This means you can create a wide range of custom products, including shirts, hoodies, hats, bags, and even custom labels, all with a single, reliable process.

Step by Step: How the DTF Process Works

Ready to see how it’s done? Here is a simple step-by-step guide to the DTF process.

- Print Your Design: The process begins by using a specialized DTF printer to print your artwork onto a sheet of transfer film. These printers use specific DTF inks, including a white base layer, to ensure colors are bright and opaque.

- Apply Powder: While the ink is still wet, the printed film is coated with a fine adhesive powder. The powder sticks only to the inked areas of the design.

- Cure the Film: The film then goes through a curing process. Using a DTF oven or another heat source, the adhesive powder is melted until it forms a smooth, even layer. Once cured, the transfer is ready to be applied.

- press: Place the transfer on your garment and press it using a heat press machine set to the correct temperature and pressure. This activates the adhesive, bonding the design permanently to the fabric.

- Peel: After pressing, you peel the film away. Depending on the film type, this can be a hot peel (peeling immediately) or a cold peel (waiting for it to cool).

For the best results, make sure your curing time is just right—undercured powder won’t bond well, while overcured powder can affect quality. Always use even pressure with your heat press and consider testing your settings on a sample piece of material first.

Why We Choose True Hot Peel at Limitless Transfers

When it comes to DTF film, you have two main options: hot peel and cold peel. A cold peel transfer requires you to wait until the garment and transfer have cooled completely before peeling the film away. While effective, this waiting period slows down your workflow, especially on large orders.

At Limitless Transfers, we exclusively use true hot peel transfers. As the name suggests, our transfers are designed to be peeled immediately after pressing, while the garment is still hot. This small difference has a massive impact on production speed. You can press, peel, and move to the next item in a continuous flow, cutting your production time significantly.

Our award-winning true hot peel transfers don’t just offer speed; they deliver superior quality. The transfers release cleanly, leaving behind a design with vivid, bold colors and fine details intact. Plus, they have a premium soft-hand feel, meaning the design is flexible and lightweight on the garment, not stiff or plastic-like. It’s the perfect combination of speed and quality.

Limitless Transfers: The DTF Partner You Can Trust

Choosing the right DTF supplier is just as important as the technology itself. At Limitless Transfers, we’re dedicated to helping you succeed. Our commitment to quality is proven by back-to-back 1st place awards for DTF printing in 2024 and 2025. We pair that award-winning print quality with industry-leading service, including same-day shipping on orders placed by noon EST and free shipping on orders over $50.

We believe in making professional printing accessible. That’s why we have no minimums on our DTF transfers—purchase one or one thousand. Our online gang sheet builder makes it easy to arrange your designs, or you can upload your own print-ready files. We support a wide range of file types to make it easy to start printing.

We are proud to be the trusted partner for creators of all sizes. Whether you are a large print shop, a growing e-commerce seller, or a hobbyist just starting out, our brand is here to provide the tools and professional results you need.

Common Questions About DTF Printing

As DTF gains popularity, a few common questions pop up. Here are some answers.

What’s the difference between DTF and sublimation?

The main difference is material compatibility. Sublimation dyes the fibers of polyester fabric, so it only works on light-colored, poly-rich materials. DTF printing, on the other hand, applies a transfer on top of the fabric, allowing it to work on cotton, polyester, blends, and dark-colored materials with no limitations.

How long do DTF transfers last?

DTF prints are known for their exceptional durability. When applied correctly, they are soft, stretchable, and can withstand dozens of washes without cracking, peeling, or fading. The durability often matches or exceeds that of traditional screen prints, making them ideal for retail-quality apparel.

Can I use any heat press?

While you don’t need a specific DTF-branded heat press, you do need a quality machine that provides consistent temperature and even pressure. Clamshell and swing-away presses both work well. Uneven pressure is a common cause of application issues, so a reliable heat press is a key part of the process for achieving a great final product.

Photo by Ryan Hoffman on Unsplash

Bringing Limitless Possibilities to Life

We built Limitless Transfers with a simple goal: to make professional-grade printing accessible to everyone. We saw the incredible potential of DTF technology to help creators bring their ideas to life without the barriers of cost, complexity, or quantity. DTF delivers fast, easy, and amazing results for any project, big or small.

From a side hustle to a full-scale brand, DTF printing opens doors. It allows for full-color designs, offers unmatched durability, and gives you the freedom to create what you want, when you want. We are incredibly proud to be a part of so many creators’ journeys and to provide a service that customers are satisfied with.

Shop our custom DTF transfers today and discover why so many creators trust our company for vibrant color, fast delivery, and a great experience every time.