As the team behind Limitless Transfers, we’ve seen it all when it comes to apparel printing. Over the years, I’ve learned that most production issues don’t come from bad transfers; they come from neglected equipment. Taking proper care of your heat press is one of the most important things you can do for your business. It protects your investment, ensures your products look professional, and upholds your brand’s reputation. Whether you’re a DIY creator just starting out or a professional apparel shop running orders all day, this guide will help you keep your press in top shape.

Understanding Your Heat Press Machine Before Problems Start

Heat Press Machine

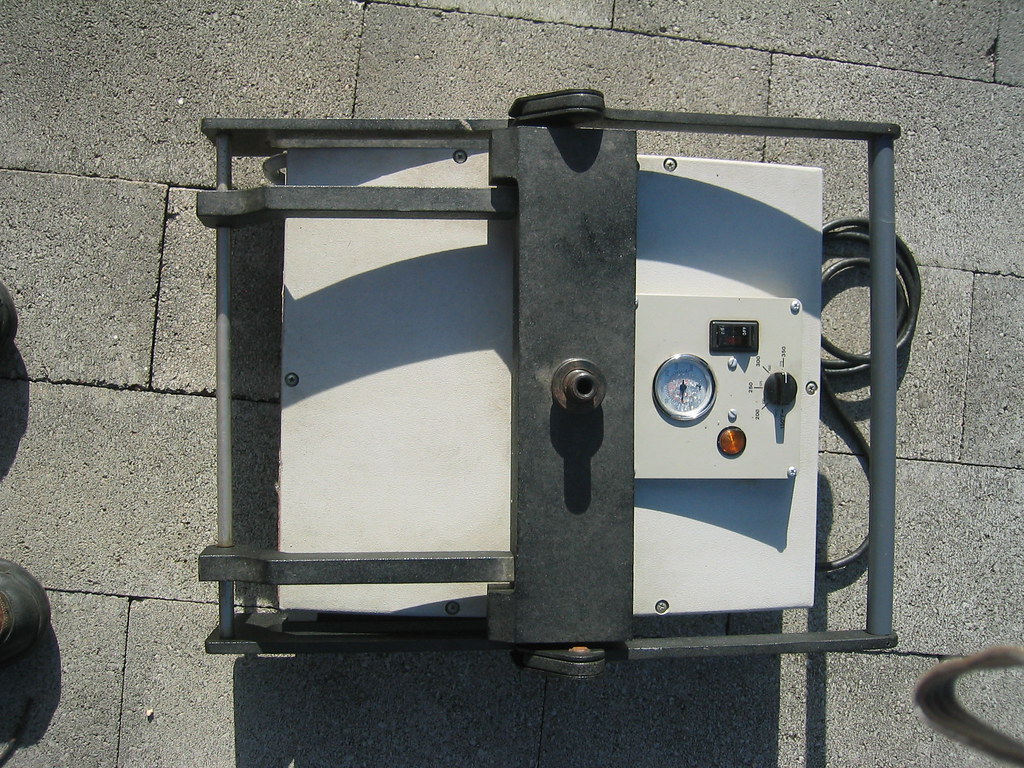

So, what does a heat press machine actually do during apparel printing? It’s more than just a hot plate. It uses controlled temperature and even pressure to transfer graphics onto a substrate. To get consistent, high-quality transfers, you need to understand its key components. The platen (the flat heating element), the pressure system, and the temperature controller all work together. When one of these parts isn’t working correctly, it can compromise heat distribution, pressure application, and the final durability of your custom creations. Knowing your device is the first step toward achieving professional results.

Daily and Weekly Heat Press Maintenance That Makes a Difference

Heat Press

You don’t need to spend hours on maintenance to see a huge difference. Simple daily habits are your first line of defense against long-term damage. At the end of each day, I recommend wiping down the exterior of your machine and checking the power cord for any signs of wear. A quick visual inspection can prevent a major headache down the line.

For small business owners, weekly checks are crucial for avoiding downtime. Once a week, take a moment to inspect the platen for any residue and test the pressure to ensure it’s even across the entire surface. These small steps help keep your production running smoothly and improve the quality of your prints on t-shirts and other surfaces.

How to Properly Clean Your Heat Press Without Damaging It

A clean press is a happy press. But it’s important to use the right tools and supplies to avoid damaging the non-stick coating on your platen. I always recommend using a soft cloth and a non-abrasive cleaner specifically designed for heat presses. Never use sharp tools or harsh chemicals.

To remove stubborn adhesive, ink, or transfer residue, heat the press to around 200°F. Then, gently rub the spot with a clean, dry cloth. The heat helps loosen the residue, making it easier to wipe away. Keeping your platens clean is essential for protecting your custom transfers and heat transfers, ensuring they adhere correctly and look flawless.

Auto Open Presses: What to Watch and What to Maintain

Auto Open

Many shops I work with love auto open presses. They are fantastic for improving workflow and production speed, as they automatically lift when the timer is done. This feature helps prevent over-pressing and allows you to multitask. However, the mechanical parts of an auto open system can experience wear.

I often see issues with the magnetic latch or the gas struts that control the lifting motion. Regularly check these common wear points. A quick check of the alignment and timing can help keep the pressure, timing, and power consistent, ensuring your press remains a reliable workhorse.

Managing Pressure, Temperature, and Heat Distribution

Over time, it’s normal for your press’s pressure and temperature settings to drift. This is why regular calibration is so important for getting the best results. An inexpensive infrared temperature gun is a great tool for testing for uneven heat distribution. Simply point it at different spots on the heated platen to check for cold spots.

If you find significant temperature differences or notice your pressure feels uneven, it’s time to recalibrate. Most machines have a manual adjustment for pressure, and your user manual can guide you through recalibrating the temperature. This ensures every transfer gets the heat and pressure it needs to look great.

Preventing Damage When Pressing T Shirts and Other Materials

T Shirts

Different fabrics require different settings. Materials like 100% cotton can handle higher heat, while polyester blends are more sensitive and can scorch if the temperature is too high. Always preheat your garments, especially dark ones, to remove moisture and wrinkles. This simple step creates a smooth, dry surface for the transfer to adhere to.

When you expand to pressing hats, caps, wood, or mugs, you might need different platens or accessories. Using the right tool for the job prevents you from putting unnecessary stress on your main equipment and opens up new product possibilities for your business.

“tshirt press” by activefree is licensed under CC BY 2.0

Heat Transfers and Custom Transfers: Protecting Your Results

Heat Transfers

The quality of your final product is a direct reflection of your process. A clean and well-maintained heat press is critical for achieving great adhesion and long-lasting durability. When residue from old ink or adhesive builds up on your platen, it can create an uneven surface.

Custom Transfers

This buildup can interfere with how our transfer film performs, leading to spots where the design doesn’t stick properly. As someone who is obsessed with quality, I can tell you that a pristine platen is key. It ensures our award-winning DTF transfers provide the soft-hand feel and vibrant color they were designed for, every single time.

Heat Press Problems I See All the Time (And How to Fix Them)

Even with great maintenance, problems can still pop up. Here are a few common issues and how to address them:

- Inconsistent pressure or fading graphics: This is often a sign of uneven heat or a worn-out platen. Test your temperature and consider if the silicone pad on your lower platen needs replacing.

- Transfers not sticking: This could be a pressure, temperature, or time issue. Double-check your settings against the transfer instructions. Also, make sure your garment was properly pre-pressed.

- Electrical or power issues: If your press isn’t heating or turning on, check the fuse and power cord first. If those look good, it might be time to contact the manufacturer for support.

Sometimes, troubleshooting is enough. But if you find yourself constantly fixing the same problem, it might make more business sense to invest in a replacement.

Supporting DTF Printers With a Reliable Heat Press Setup

DTF Printers

Your heat press is the final, critical step in the DTF printing process. The advanced ink and film used by modern DTF printers rely on accurate heat press performance to cure properly and bond to the fabric.

Proper maintenance protects the entire system. A press with accurate temperature and pressure ensures the vibrant colors from your printer are perfectly replicated on the final garment. For shops looking to scale their production, I always recommend a reliable, well-maintained heat press as a non-negotiable part of their setup. It’s what turns a great print into a great product.

Extending the Life of Your Heat Press as Your Business Grows

As your business grows, think about smart ways to support your equipment. Using accessories like platen protectors and interchangeable platens can reduce wear and tear on your main press. These tools can also enhance versatility, allowing you to easily expand into new products.

There will come a point where upgrading makes more sense than continuing to repair an old machine. A new press can offer better features, more consistency, and the reliability you need to take your business to the next level. Investing in your equipment is investing in your growth.

A Well-Maintained Press Protects Your Business

At the end of the day, caring for your heat press is a fundamental part of running a professional operation. It’s not just about protecting a piece of equipment; it’s about ensuring efficiency, consistency, and customer satisfaction. Your heat press is the foundation of your production, so treat it with the care it deserves.

Helpful Guides and Cleaning Tools

Here are a few resources to help you maintain a pristine heat press:

- OSHA’s Guide to Hand and Power Tools: While broad, this government resource offers crucial safety standards for operating heated machinery. Understanding basic electrical and thermal safety is the first step in responsible machine maintenance.

- EZ-Off Heat Press Cleaner Instructions: This is often considered the gold standard for cleaning hot platens. Even if you don’t use this specific brand, their usage guides provide excellent general advice on how to safely apply cleaning pastes to hot surfaces without causing damage.

- YouTube: “How to Clean a Teflon Sheet”: A quick search for this topic yields numerous generic tutorials from crafting enthusiasts. Watching a visual demonstration of how to wipe down and preserve your protective sheets can extend their life significantly.

- Teflon™ Industrial Coatings Maintenance Guide: Accessing technical data sheets or care guides from manufacturers of PTFE (Teflon) coatings can give you the scientific dos and don’ts of the material. This ensures you aren’t using abrasive chemicals that strip the non-stick properties of your platen.

- Digital Decorating Forums (like T-Shirt Forums): Online communities often have dedicated “Equipment Maintenance” sections. Searching these archives allows you to see real-world problems others have faced and the community-vetted solutions that worked for them.

- Local Hardware Store “High-Temp Grease” Selection: Browsing the catalog of a major hardware supplier (like Home Depot or Lowe’s) for “Lithium Grease” or high-temp lubricants helps you identify the right product for your pivot points. Look for product descriptions that mention heat resistance ratings.

- Isopropyl Alcohol Safety Data Sheet (SDS): Simple rubbing alcohol is a staple for cleaning the cool outer shell of your press. Reading a standard SDS for Isopropyl Alcohol helps you understand its flammability and evaporation rates, ensuring you use it safely away from the heating element.

Conclusion

By utilizing these resources, you can build a robust maintenance routine that protects your investment. Regular care not only extends the life of your heat press but also ensures consistent, high-quality transfers for your customers. Take a moment to explore these links and stock up on the necessary supplies today.

Press With Confidence Using Limitless Transfers

A great heat press deserves great transfers. Our award-winning, true hot-peel DTF transfers are designed to give you flawless results when paired with a properly maintained press. With our user-friendly gang sheet builder, same-day shipping, and no minimum orders, we make it easy for creators and professionals to succeed.

Ready to create with confidence? Explore our high-quality DTF transfers, heat presses, and supplies. We’re here to be your long-term partner in creation.