Are you wanting to learn how to make DTF transfers?

Looking to create vibrant, high-quality prints that work on any fabric? DTF (Direct to Film) transfers might be your new go-to solution. With their growing popularity among small businesses, creative entrepreneurs, and custom apparel enthusiasts, DTF transfers open up endless possibilities for designing t-shirts, hoodies, tote bags, hats, and more.

At Limitless Transfers, we specialize in making this process seamless, offering expert-curated supplies and tools so anyone can achieve professional-grade results. Whether you’re curious about starting your own DTF setup or simply looking for an easier way to get custom prints, this guide has you covered.

Here’s what you’ll learn:

- What DTF transfers are and why they’re worth it

- The tools and materials needed for DTF printing

- A step-by-step process to make and apply your own dtf transfers

- Insider tips for flawless results

Dive in, and by the end, you’ll wonder why you didn’t start sooner!

What Are DTF Transfers?

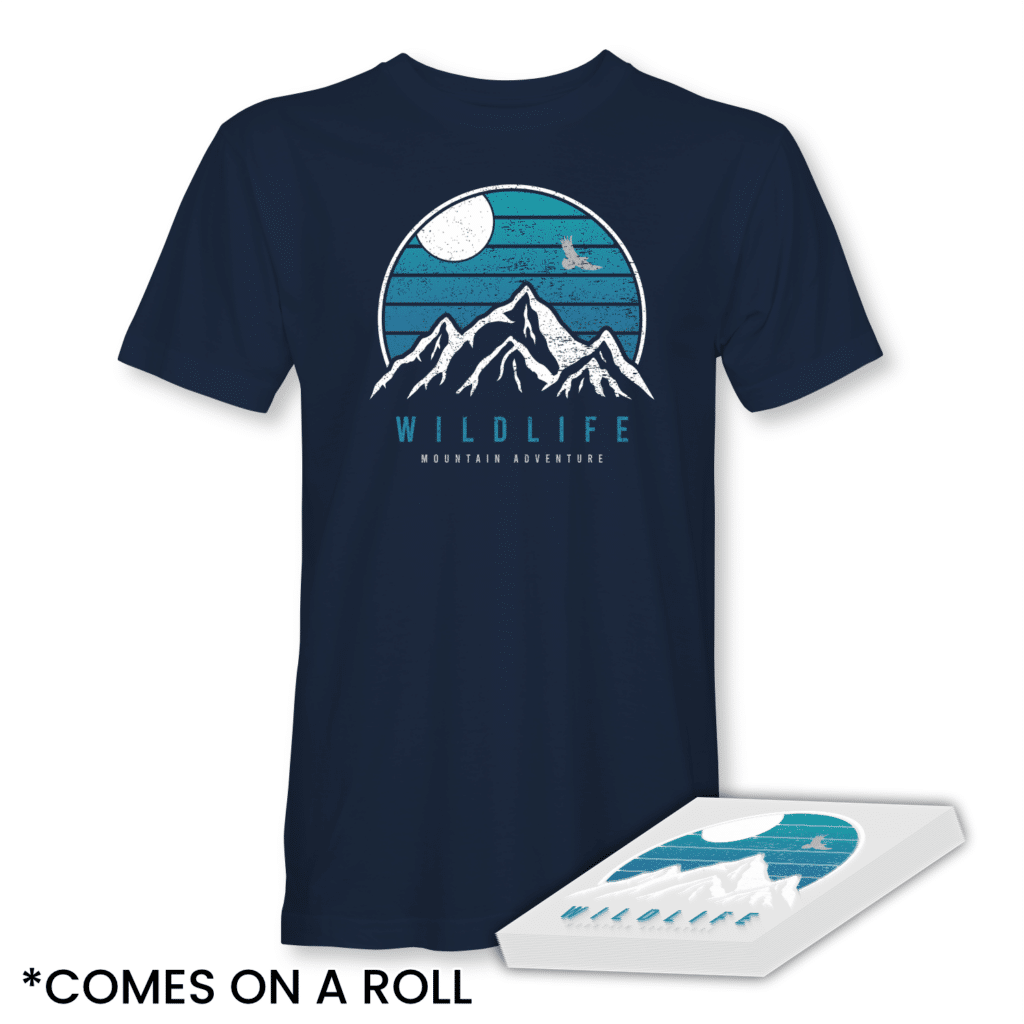

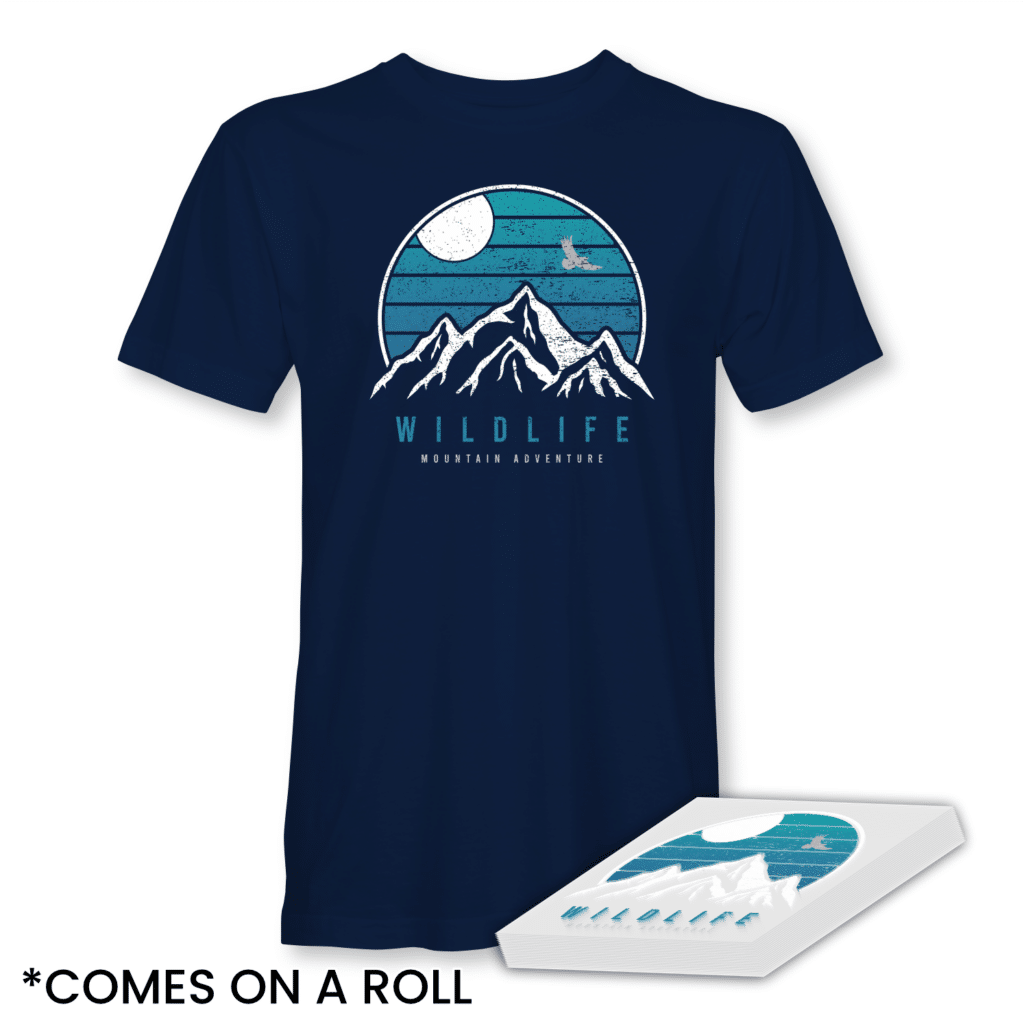

DTF stands for Direct to Film, a cutting-edge printing process where designs are printed onto a special film and then transferred to fabric using a heat press. DTF transfers open up endless possibilities for designing t-shirts, hoodies, tote bags, hats, and more. Applying DTF transfers to a t shirt is one of the most common and effective uses, making it a popular choice for custom apparel.

Unlike other printing methods like sublimation or screen printing, DTF transfers are compatible with virtually any material, from cotton to polyester and even nylon blends.

Why DTF Transfers Stand Out:

- Versatility: Works on a wide variety of surfaces, including t-shirts, hoodies, bags, and more, making it easy to customize any garment with your unique designs.

- High Color Vibrancy: Creates sharp and vivid designs, even on dark fabrics.

- Durability: Transfers hold up well against multiple washes and heavy wear.

- Ease of Use: No need for expensive setups or advanced skills.

Compared to traditional methods like sublimation, which requires polyester surfaces, or vinyl, which lacks the same fine detail, DTF transfers combine flexibility and quality for a superior result.

Can You Print DTF with a Regular Inkjet Printer?

Unfortunately, you can’t use a standard inkjet or laser printer to create DTF transfers. While a regular inkjet printer is not suitable for DTF transfers, some specialized DTF printers are actually modified versions of inkjet printers designed to handle DTF film and inks. DTF printing requires specialized equipment capable of handling specific inks and films.

What Makes Standard Printers Unsuitable:

- Ink Type: Regular printers use water-based or toner ink—not the DTF pigment inks required for vibrant designs.

- Film Handling: Printers need to handle DTF film, which is thicker and more heat-sensitive than standard paper.

Instead, investing in a DTF printer is essential to achieve the accuracy and color vibrancy you’re aiming for.

Note: Using the wrong type of printer or ink can result in poor print quality or failed transfers.

Can You Do DTF with a Cricut?

Cricut machines are fantastic for cutting vinyl and similar materials, but they’re not designed for printing. While you might use a Cricut to cut out pre-printed DTF designs, the printing and transfer process itself requires specialized tools, like a DTF printer and a heat press.

Bottom Line:

Cricut machines play a complementary role but can’t handle the core DTF transfer process.

Choosing the Right DTF Printer

Selecting the right DTF printer is a crucial step in producing high-quality DTF transfers. The type of fabric you plan to print on and the level of print quality you desire should guide your decision. DTF printers equipped with high quality pigment inks deliver superior adhesion and color vibrancy, ensuring your designs look sharp and last through many washes.

Inkjet printers that are specifically designed for DTF printing are ideal, as they offer excellent compatibility with DTF film and dtf powder. Pay close attention to the printer’s resolution and printing speed—higher resolution means finer detail, while faster speeds help you keep up with demand. A user-friendly interface and adjustable printer settings can make the heat press process smoother and more efficient.

Before making a purchase, research different DTF printer models and read reviews to find one that fits your needs and budget. Consider not only the initial cost of the printer, but also the ongoing expenses for dtf ink, dtf powder, and other consumables. Some DTF printers come with built-in cutters, which can save you time and boost productivity, especially if you’re handling more prints.

Make sure your chosen DTF printer is compatible with your computer and design software, so you can streamline your workflow from design to transfer. Investing in a high-quality DTF printer will help you consistently produce professional-looking DTF transfers with ease.

What Do You Need to Start DTF Printing?

Getting started with DTF doesn’t have to be complicated. Here’s your essential checklist:

- DTF Printer: Specialized printers handle DTF film and pigment inks for clear, vibrant printing.

- DTF Ink: This includes colored pigment inks and white ink to ensure your designs pop on any fabric.

- DTF Film: A heat-resistant film where designs are printed (ensure you’re printing on the matt side for the best results). DTF film is available in both sheets and rolls, allowing for flexibility in production.

Note: it’s much cheaper to buy your DTF Transfers than to print your own DTF Transfers! Limitless Transfers will gladly be your parnter in creating your vision. We’ll replace any other vendor you may already use!

- DTF Powder: Acts as an adhesive for transferring the design to your fabric. Sprinkle a bit of powder over the printed design for even coverage. It’s crucial that the powder adheres evenly to your printed design.

- Heat Press: Essential for curing the powder and transferring the design onto fabric. Look for a machine that allows for accurate temperature and medium pressure settings.

- Design Software: Programs like Photoshop or Canva help you create or edit designs before printing.

- Curing Unit (Optional): While many use a heat press to cure the DTF powder, a curing oven provides more consistent results for larger batches.

At Limitless Transfers, we offer a one-stop shop for all of these materials, so you’re always covered.

For best results, pre press the fabric to remove moisture and wrinkles before applying the transfer.

5 of the Best Options for a Heat Press Machine

Choosing the right heat press machine is crucial for achieving flawless transfers. Here are five highly-rated options for professionals and small businesses, ensuring quality and reliability:

- Cricut EasyPress 3 | Why it’s great: Lightweight, portable, and user-friendly, this machine is perfect for small-scale projects and beginners. Learn more

- Fancierstudio Power Heat Press | Why it’s great: Known for its durability and affordability, this 15 x 15-inch clamshell model is ideal for larger orders. Learn more

- Geo Knight Digital Swing-Away Heat Press | Why it’s great: A premium option with precise temperature control and a swing-away design for maximum ease of use. Learn more

- PowerPress Industrial-Quality Heat Press | Why it’s great: Designed with commercial use in mind, this machine delivers consistent results with heavy-duty construction. Learn more

- Hix SwingMan Heat Press | Why it’s great: This professional-grade model is praised for its innovative technology, ensuring perfect heat and pressure distribution. Learn more

Each of these machines offers distinct benefits and is compatible with Limitless Transfers’ hot peel DTF transfers, making them excellent choices for vibrant, high-quality printing results.

Preparing DTF Ink and Working with DTF Film

Proper preparation of DTF film is essential for achieving the best print quality and ensuring your designs transfer smoothly onto fabric. Start by cutting your DTF film to the correct size, always making sure the matt side is facing up when loading it into your printer. Handle the film carefully to avoid scratches or damage that could affect the final image.

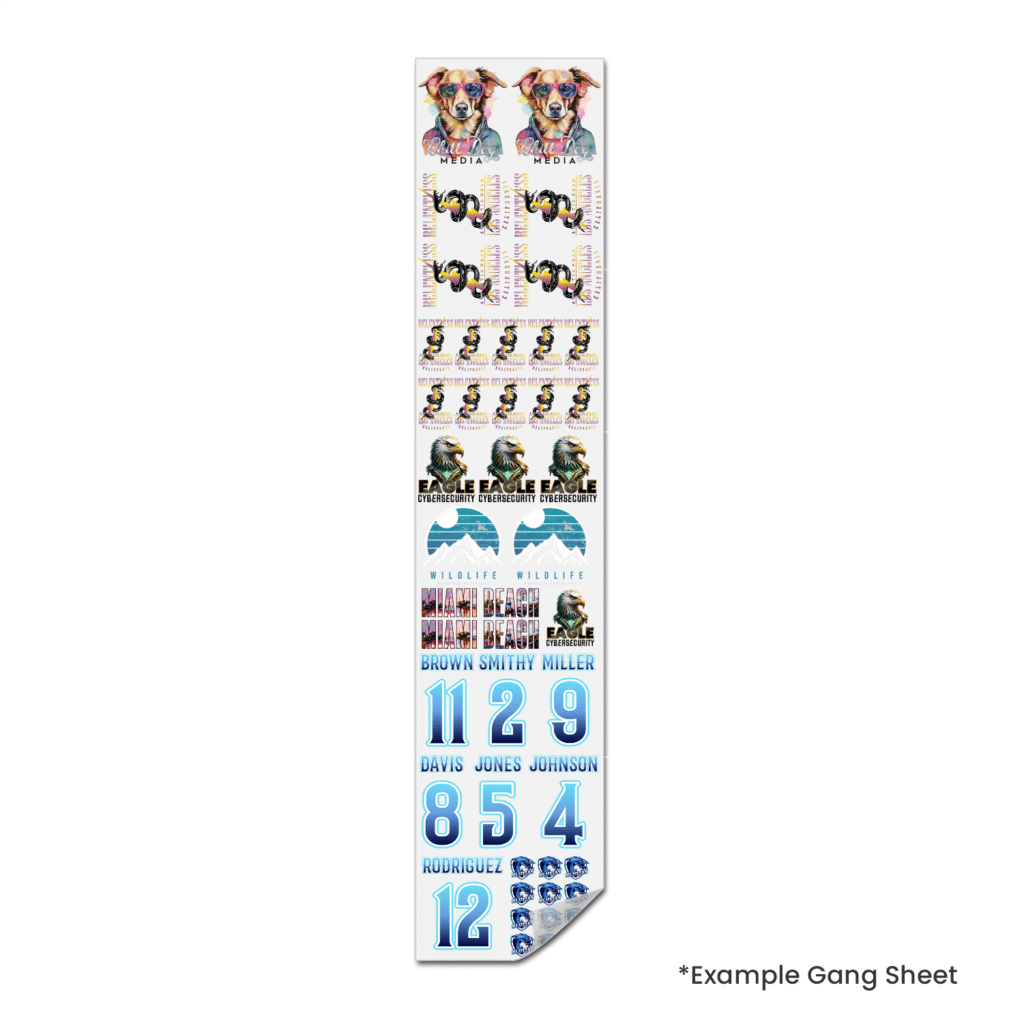

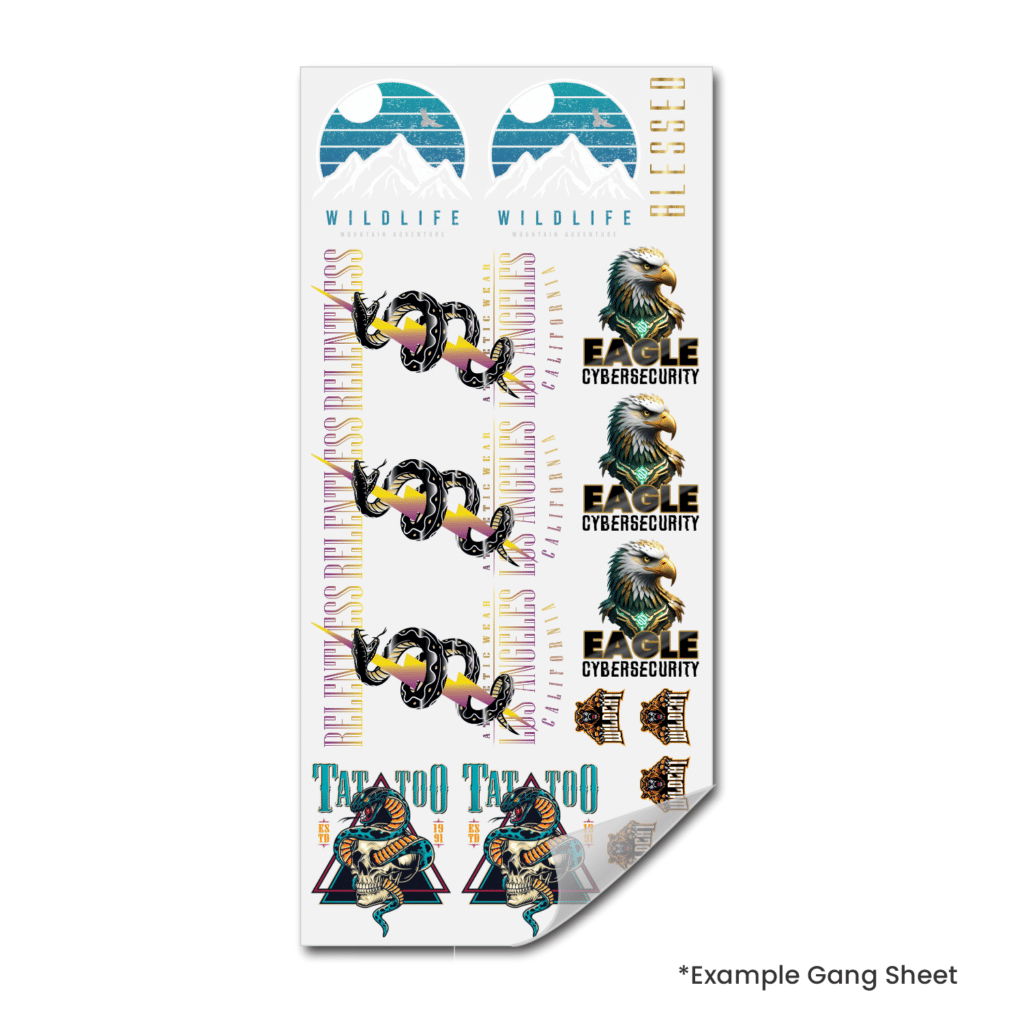

Before printing, use a lint roller to remove any dust or debris from the DTF film. This simple step helps prevent imperfections in your printed design. Once your design is printed, apply a thin, even layer of DTF powder to the wet ink, making sure the entire image is covered. Gently shake or brush off any excess powder before moving on to the next step.

DTF film comes in various sizes and formats, including rolls and sheets, so choose the type that best fits your workflow. Store your DTF film in a cool, dry place to maintain its quality and prevent warping or sticking. Always use film that is specifically designed for DTF printing, and follow the manufacturer’s instructions for preparing and handling it.

With practice, you’ll develop the skills needed to work efficiently with DTF film and consistently achieve vibrant, high-quality prints.

Easy Steps | How to Make DTF Transfers

Now that you have your tools, here’s a quick overview of the process using a handy heat press to ensure professional results:

1. Print Your Design

- Load your DTF film into the printer with the matt side facing up.

- Use DTF-compatible inks (including white ink) and ensure your printer settings are optimized for high-resolution results.

- Handle the printed film carefully to avoid any smudge of the wet ink.

2. Apply DTF Powder

- Sprinkle DTF powder over the freshly printed design while the ink is still wet. Be careful not to touch or disturb the wet ink to avoid smudging the design.

- Shake off the excess powder to avoid uneven adhesion.

3. Cure the Powder

- Place the film under a heat source (like your heat press or a curing oven) until the powder melts and forms a semi-glossy adhesive, ensuring the powder will properly adhere to the printed design for a durable transfer.

4. Transfer to Fabric

- Place the cured design face-down on your chosen material (cotton, polyester, or blends), making sure the design is centered on the fabric for a professional look.

- Use a heat press set to the required temperature and apply medium pressure for a few seconds, heat pressing the design onto the fabric.

The adhesive powder ensures the design sticks securely to the fabric after pressing.

5. Peel and Finish

- Allow the transfer to cool (or use a hot peel technique for faster results, depending on your film). For best results, peel the film while it is still warm or at the recommended temperature.

- Peel away the film to reveal your vibrant, durable design.

Be sure to allow the transfer to cool properly after peeling to prevent cracking of the design.

Applying DTF Transfers Step-by-Step

Here’s a detailed breakdown of how to apply DTF transfers for the best results:

- Preheat the Fabric: Use the heat press to preheat your fabric for 5 seconds. This removes moisture and creates a smooth surface.

- Position the Design: Lay the DTF transfer on the fabric, ensuring proper alignment.

- Apply Heat: Press the design using medium pressure at 320°F for 15-20 seconds.

- Cool and Peel: Allow the transfer to cool (if using cold peel) or peel immediately (if using hot peel).

- Final Press: For added durability, press the design again for 5 seconds.

If you encounter issues like ink bleeding or powder residue during the application process, you can deal with these problems by adjusting your heat press settings or ensuring the fabric is properly preheated.

Safety Precautions for DTF Transfer Production

Safety should always be a top priority when working with DTF transfers. Wear protective gear such as gloves, safety glasses, and a mask to shield yourself from dtf powder and dtf ink fumes. Make sure your workspace is well-ventilated to minimize inhalation of any airborne particles or vapors.

Keep your area clean and organized to prevent spills and accidents, and always follow the manufacturer’s instructions for handling dtf ink, dtf powder, and other materials. When using a heat press, ensure it has accurate temperature control to avoid burns or injuries during the heat press process.

Keep children and pets away from your workspace, and avoid touching your face or eyes when handling dtf materials. After working, wash your hands thoroughly to remove any residual ink or powder. Dispose of dtf waste and materials according to proper safety protocols to protect both yourself and the environment.

By following these safety precautions, you can enjoy the creative process of making DTF transfers while keeping your workspace safe and healthy.

Tips for Perfect Results Every Time

- Use high-quality pigment inks for vibrant designs.

- Ensure that the DTF powder adheres evenly to the printed design.

- Experiment with printer settings to achieve optimal print clarity and detail.

- Always use a heat press with precise temperature control.

- Allow designs to fully cure for long-lasting adhesion and color.

Troubleshooting Common Problems with DTF Transfers

Even with the best equipment and preparation, you may encounter issues when producing DTF transfers. If your transfer isn’t adhering to the fabric, double-check your heat press temperature and pressure settings—both are crucial for proper adhesion. Adjust your printer settings to ensure dtf ink is being applied correctly and evenly.

Clumps or uneven distribution of dtf powder can also cause problems, so always check the powder before applying it to your printed design. Make sure your fabric is pre-pressed and free of wrinkles, as a smooth surface helps the transfer stick better. If you notice the transfer peeling off after pressing, inspect the quality of your adhesive powder and dtf ink.

Curing time and temperature are also important—if the dtf powder isn’t fully activated, the transfer may not bond properly. Examine your dtf film for scratches or damage that could affect print quality, and consider using a dtf printer with a built-in cutter for more precise cuts.

Always consult the manufacturer’s instructions for troubleshooting tips, and remember that practice and experience will help you quickly identify and resolve common issues with dtf transfers.

Advanced DTF Transfer Techniques

Once you’ve mastered the basics, you can experiment with advanced DTF transfer techniques to create truly unique designs. Try combining different dtf ink and dtf powder colors to achieve multi-colored or textured effects. Using a heat press with precise temperature control allows you to fine-tune the curing process for special finishes.

For a raised, 3D effect, apply multiple layers of dtf powder before curing. High-resolution settings on your dtf printer enable you to capture intricate details and fine lines in your artwork. You can also blend dtf transfers with other printing methods, such as sublimation or screen printing, to produce complex, layered designs.

Explore printing on various fabric types and textures to discover new effects, or use dtf transfers to decorate curved or irregularly shaped surfaces. For added protection and longevity, consider applying a clear coat or laminate over your finished transfer.

The world of DTF printing is full of creative possibilities—don’t be afraid to experiment and push the boundaries to develop your own signature techniques!

Caring for DTF Transfers

Once your garments are ready, follow these care tips to maintain their quality:

- Wash inside-out in cold water.

- Avoid using harsh detergents or bleach.

- Tumble dry on low or hang dry to prevent wear.

- Do not iron directly on the design.

By following these steps, your DTF transfers will look as vibrant on the tenth wear as they did on the first.

Why Choose Limitless Transfers for Your DTF Needs?

At Limitless Transfers, we take the hassle out of DTF printing so you can focus on what matters most. Here’s why customers love us:

- No Setup Fees: Perfect for small businesses and entrepreneurs.

- Free Shipping on Orders Over $50: Save costs while enjoying premium quality.

- Unmatched Versatility: Compatible with any fabric type, from cotton to blends.

- Vibrant Colors, Guaranteed: Our cutting-edge DTF printers deliver perfect results every time.

- Comprehensive Support: Whether you’re starting out or scaling up, we’re here to help.

Order Your Own DTF Transfers Today

Whether you’re an aspiring designer or an established business owner, Limitless Transfers makes it easy to get started with DTF printing. Explore our products, request a free sample, or start designing your own transfers today.